Sponge cutting machine

Working with sponges requires precise, efficient cutting, and sometimes even cutting into complex shapes. Therefore, when working in the field of upholstery, packaging, mattresses, or industry, a sponge cutting machine is a key tool that can save time, ensure a quality result, and adapt to changing needs. There are a variety of models on the market – from manual machines to advanced automatic systems. So how do you choose the right one?

Types of cutting machines – which one is right for you?

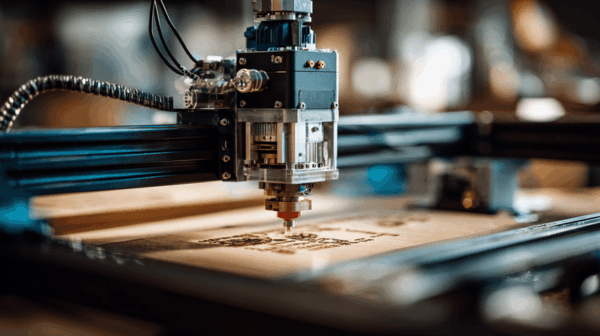

The first step in choosing is to understand what type of machine you really need. There are horizontal cutting machines, vertical cutting machines, band saws, laser cutting machines, and even CNC Advanced for precise 3D cutting. If you are making simple cuts and the volume of work is low – a manual solution may be sufficient. On the other hand, factories or businesses with constant and precise demand will prefer an automatic machine that will improve efficiency and accuracy. Each type has advantages and disadvantages – so it is important to match the machine to the type of work and its scope.

Accuracy, speed and safety at work

When choosing a professional cutting system, the three main parameters that need to be considered are: accuracy, speed and safety. A quality machine will allow for uniform and smooth cutting – even in unconventional shapes. It is important to check whether there is control over the cutting depth, the possibility of pre-programming, and protective measures to prevent injuries. Maintenance is also important – a machine that is easy to clean and maintain will last a long time and work continuously, as well as the availability of spare parts, technical service available in the area and smart software support for ongoing monitoring and control..

Adaptation to industrial and business needs

Beyond functionality, it is worth examining the suitability of the machine for your workspace, the nature of production and the ability to integrate into an existing line. Businesses in the mattress or upholstery sector, for example, will prefer machines that are capable of working with large quantities of different types of sponges. It is worth choosing a supplier that also offers after-sales service, training on machine operation and the possibility of customization. In addition, training should be provided on preventive maintenance, rapid availability of spare parts, 24/7 technical support and an extended warranty on demand, to ensure that the investment pays for itself in a short time..

A sponge cutting machine is an integral part of precise, fast and safe work in many industries. With us you will find diverse solutions – from manual machines to advanced automatic systems, customized to your needs. Contact us today for professional advice and we will be happy to help you choose the machine that will upgrade your work process and improve your business performance.

Additional articles:

איך מכונת פייבר לייזר ממירה אנרגיה לחום: כל מה שצריך לדעת על טכנולוגיית הלייזר

פתחו עסק רווחי בעזרת מכונת חיתוך ולייזר

מכונות כיפוף צינורות נירוסטה

We are here to help with any issue or question.