The Complete Guide to Laser Cutting Machine Maintenance: Mastering the Technology and Safety

In the modern industrial world, machines Laser cutting They are essential tools for producing precision products from metals and other materials. However, to ensure maximum performance, it is important to perform regular and proper maintenance on these machines. In this article, we will reveal the secrets to maintaining laser cutting machines, from a basic understanding of the technology to the most advanced techniques.

Understanding laser cutting technology

How Laser Cutting Technology Works: Principles and Processes

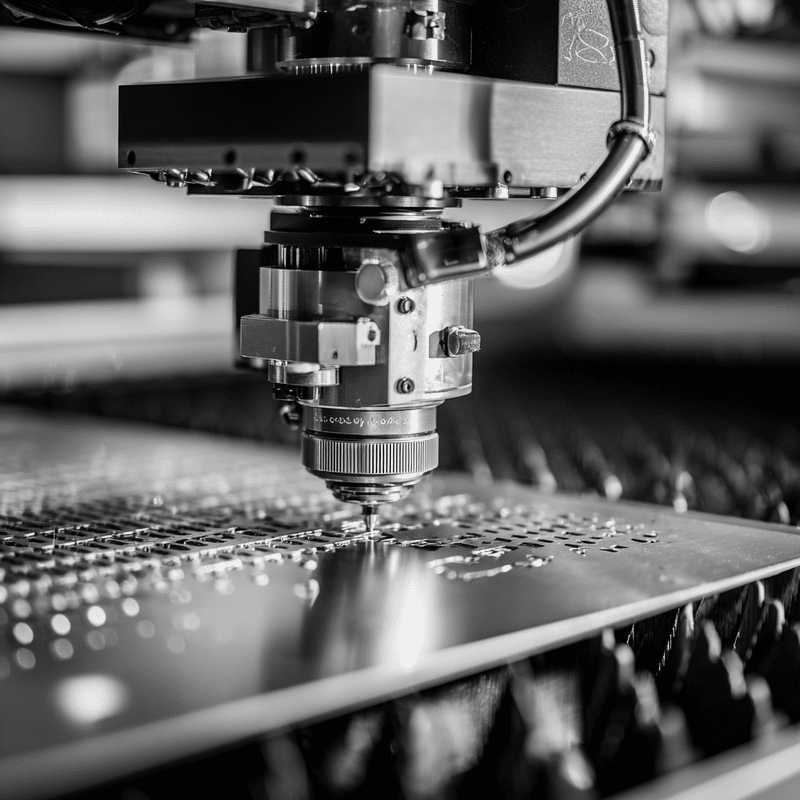

Cutting machines Lasers use a focused laser beam to cut materials by melting or thermally destroying them. The laser is focused on a single point and heats the material to the point of melting or vaporizing. The laser beam travels along a defined path to create the desired shape.

Types of laser cutting machines: CO2, fiber and more

There are several main types of laser cutting machines:

- CO2 laser machines: These are the most common machines, using carbon dioxide gas as the energy source for the laser. They are suitable for cutting non-ferrous metals, plastics and wood.

- Fiber laser machines: These machines use optical fibers as the energy source for the laser. They are more efficient than CO2 machines, and are particularly suitable for For cutting various metals Like steel.

- Diode laser machines: These use chip diodes as the energy source for the laser. They are relatively inexpensive, but less efficient than other types.

Laser Cutting Applications: Industries and Materials

Laser cutting is used in many industries, including:

- Automotive industry: for cutting metal parts for vehicles

- Metal industry: for cutting pipes, profiles and complex parts

- Construction industry: for cutting steel and iron products

- Aeronautics industry: for cutting precise parts from light metals

Laser cutting can work on a variety of materials, including ferrous and non-ferrous metals, plastics, wood, glass, and more.

The importance of regular maintenance of laser cutting machines

Extending machine life and ensuring accuracy

Proper and professional maintenance of Laser cutting machines Extends their lifespan and ensures high precision over time. When a machine is properly maintained, its components remain in good condition and operate optimally. This prevents rapid wear and malfunctions, and allows for precise cutting of parts according to plans.

Minimizing downtime and maximizing productivity

Proper maintenance prevents unexpected breakdowns and incidents that could cause your machine to fail. By performing preventative maintenance and troubleshooting in advance, downtime can be minimized and machine productivity can be maximized. This is especially essential in industries where time is of the essence.

Ensuring safety in the work environment and compliance with regulations

Laser cutting machines operate at high temperatures and use hazardous gases and energy. Proper maintenance ensures that all safety systems are working properly and that the machine complies with relevant safety regulations. This prevents accidents and protects workers from risks.

Laser cutting machine components and maintenance tasks

Laser source: cleaning, alignment and spare parts

The laser source is the beating heart of the machine, so it is important to keep it clean and properly aligned. On CO2 machines, the tubes should be cleaned and the gas replaced regularly. On fiber machines, the optical fibers should be cleaned and the diodes replaced as they wear out.

Optics: lens cleaning, mirror alignment and beam delivery

The machine's optical system, which includes lenses and mirrors, is responsible for guiding and focusing the laser beam. Dirty lenses or mirrors that are not properly aligned will cause inaccurate cutting. Therefore, it is important to clean the lenses and calibrate the mirrors regularly.

Movement system: lubrication, calibration and troubleshooting

The machine's motion system, which includes motors, rails, and cables, is responsible for moving the laser beam along the desired path. It is important to regularly lubricate the moving parts, calibrate the system, and test it for faults to ensure smooth and accurate movement.

Suction and filtration system: replacing air filters and cleaning ducts

during Laser cutting Hazardous smoke and gases are emitted. The machine's suction and filtration system is designed to safely remove these emissions. It is important to replace the air filters and clean the suction ducts regularly to ensure maximum system efficiency.

Electrical and control systems: firmware updates and fault diagnosis

The electrical systems and the computer that controls the machine are responsible for its precise operation. It is important to update the firmware regularly and perform fault diagnostics to identify and resolve problems in real time. This prevents disabling faults and ensures smooth operation.

Developing a maintenance plan for laser cutting machines

Preventive maintenance schedules and lists

To perform effective maintenance, it is important to develop preventive maintenance schedules and checklists. These will define the required actions and the frequency with which they should be performed, such as cleaning lenses, replacing filters, lubricating, and calibrating.

Monitoring and documenting machine performance

Machine performance should be monitored regularly and any faults or anomalies recorded. This data can help detect recurring problems and identify the need for preventative maintenance or service.

Spare parts inventory and supplier relationships

In order to perform efficient maintenance, it is important to maintain an adequate stock of spare parts. It is also important to develop good relationships with reliable suppliers who can deliver parts quickly when needed.

Training and certification of maintenance staff

Proper maintenance of laser cutting machines requires unique knowledge and skills. Therefore, it is important to train the maintenance team and authorize them to perform the various tasks. Professional training ensures high-quality and safe maintenance.

Solving common problems with laser cutting machines

Identifying and resolving cut quality issues

Sometimes there may be problems with the cut quality, such as rough edges, scratches or inaccuracies in dimensions. Possible causes for this are dirty lenses, misaligned mirrors, problems with the motion system or incorrect settings. By identifying the source of the problem, it can be corrected and the cut quality improved.

Diagnosing and repairing mechanical and electrical faults

Sometimes there may be faults in the mechanical or electrical systems of the machine, such as motor faults, cable problems or electrical shorts. It is important to diagnose the problem quickly and fix it by replacing the faulty parts or calibrating the systems.

Addressing problems related to the laser source and optics

Problems with the laser source or optical system can cause inaccurate cutting, weak cutting force, or other problems. Identifying the source of the problem, such as dirty lenses, misaligned mirrors, or a worn laser source, will allow you to properly address it.

Advanced techniques for maintaining laser cutting machines

Forward-looking maintenance implementation with Internet of Things (IoT) and data analytics

Advanced technologies such as Internet of Things (IoT) And data analytics enable predictive maintenance on laser cutting machines. By installing sensors and monitoring systems, real-time data can be collected on machine performance, wear levels, and early warning signs of failure. Analyzing this data allows patterns to be identified and maintenance needs to be predicted before problems occur, reducing downtime and improving efficiency.

Automate maintenance tasks using robotics and artificial intelligence (AI)

Robotic and artificial intelligence technologies can help automate routine maintenance tasks on laser cutting machines. Robots can perform tasks such as cleaning lenses, replacing filters and greasing, while artificial intelligence can assist in fault analysis and maintenance decision-making. This automation reduces the need for human resources and improves the efficiency and accuracy of maintenance operations.

Integrating laser cutting machine maintenance into Industry 4.0 initiatives

Laser cutting machine maintenance is an important part of the transition to Industry 4.0 – the digital and computerized industry. By Integrating advanced technologies As IoT, data analytics, robotics, and artificial intelligence in maintenance processes, higher levels of efficiency, accuracy, and transparency can be achieved in the operation of laser cutting machines.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.