Fiber Laser Engraving: A Guide to Recommended Thicknesses by Power and Material Characteristics

The world of laser engraving and cutting is an advanced technology that allows businesses and entrepreneurs to produce products with a high level of precision and quality. One of the important factors in the success of the process is choosing the appropriate material thickness according to the power of the laser machine. In this article, we will discuss the recommended thicknesses for fiber laser engraving according to the power of the machine, focusing on different materials and specific applications.

Understanding laser engraving capabilities

What is fiber laser engraving?

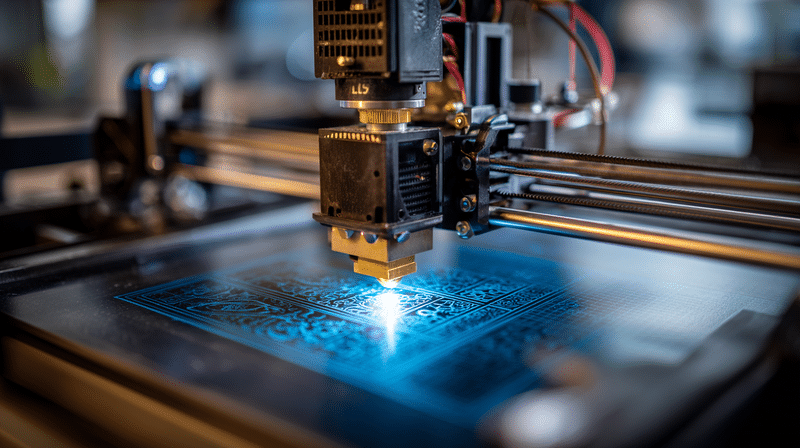

Fiber laser engraving is an advanced technique for processing materials using a high-power laser beam. The laser focuses a lot of energy on a small area, allowing for deep engraving, precise cutting, and high-quality finishing of a variety of materials, such as wood, plastic, glass, and metals.

Factors affecting engraving depth and quality

Laser power and speed

The power of the laser beam and the speed at which it moves across the material directly affect the depth of the engraving and the quality of the result. The higher the power and the slower the speed, the greater the engraving depth.

Material properties and composition

Different materials respond differently to laser engraving depending on their physical and chemical properties. For example, hard metals will require a higher laser power to engrave than wood or plastic. The chemical composition of the material also affects the absorption of laser energy and the quality of the engraving.

Choosing the appropriate material thickness

Low-power laser machines (20-30 watts)

Suitable for thin materials and superficial marking

Laser machines At low power, they are suitable for superficial engraving on thin materials such as cardboard, paper, thin wood and plastic up to 3 mm thick. They are ideal for marking, engraving logos and short texts.

Recommended thicknesses for common materials:

- Wood: up to 3 mm

- Acrylic/Plastic: Up to 3 mm

- Paper/cardboard: up to 1 mm

Medium power laser machines (40-80 watts)

Versatile for engraving and light cutting

Laser machines with power Medium allows for deeper engraving and also cutting of relatively thin materials. They are suitable for a wide range of applications, including engraving signage, wood products and gifts.

Optimal thicknesses for different applications:

- Engraving on wood: up to 10 mm

- Wood cutting: up to 6 mm

- Engraving on acrylic/plastic: up to 6 mm

- Acrylic/Plastic Cutting: Up to 4mm

High-power laser machines (over 100 watts)

Deep engraving and cutting capabilities

High-power laser machines allow for extremely deep engraving and cutting of thick materials, including metals. They are common in industries such as furniture manufacturing, the automotive industry, and metal products.

Recommended maximum thicknesses:

- Engraving on wood: up to 25 mm

- Wood cutting: up to 15 mm

- Engraving on acrylic/plastic: up to 12 mm

- Acrylic/Plastic Cutting: Up to 10mm

- Engraving on metal: up to 6 mm

- Metal cutting: up to 4 mm

Material-specific thickness guide

Engraving on wood

Considering Hardwood vs. Softwood

The type of wood affects the depth of engraving possible. Hardwoods like oak or bamboo require a higher laser power for deep engraving than softwoods like pine or poplar.

Ideal thicknesses for different types of wood:

- Hardwoods (oak, bamboo): up to 6 mm

- Softwoods (pine, poplar): up to 10 mm

Engraving on acrylic and plastics

Differences between cast and extruded acrylic

Cast acrylic is a more uniform material and allows for deeper engraving than extruded acrylic, which may be uneven and contain air bubbles that make quality engraving difficult.

Recommended thicknesses for plastics:

| Plastic type | Maximum engraving thickness | Maximum cutting thickness |

|---|---|---|

| Cast acrylic | 12 mm | 10 mm |

| Extruded acrylic | 6 mm | 4 mm |

| Polypropylene | 6 mm | 4 mm |

Engraving on metals

Engraving on rough metal vs. smooth metal

Rough or anodized metals allow for better engraving than smooth metals, which can cause laser reflection and impair engraving quality.

Thickness limits for different types of metal:

- Rough/coated aluminum: up to 6 mm

- Rough iron: up to 4 mm

- Rough stainless steel: up to 3 mm

חברת אוורסט יבוא מכונות בע"מ היא מהמובילות בישראל בתחום ייבוא מכונות לייזר מתקדמות לתעשייה, עם התמחות מיוחדת במכונות פייבר לייזר לחריטה, כיפוף וחיתוך מתכות. החברה מספקת ייעוץ מקצועי וטכני, מחירים תחרותיים ושירות מקיף.

Advanced laser engraving techniques

Engraving in multiple passes for deeper cutting

Sometimes, to achieve deeper engraving on thick materials, multiple passes of the laser can be made over the same area. Each pass deepens the engraving until the desired depth is achieved.

Combining engraving and cutting

Engraving and cutting can be combined in the same process, for example by engraving a pattern or text on a part of a product and then cutting out the exact shape.

Masking and layering techniques

Using special masking materials or creating layers of different materials allows for unique engraving effects, such as engraving in different colors or engraving at varying depths.

Safety considerations and recommended work practices

Laser Safety Guidelines

It is important to follow safety rules when working with a laser, including using special protective glasses, keeping flammable materials away, and avoiding looking directly into the laser beam.

Proper ventilation and fume removal

The laser engraving process may emit fumes and smoke, so it is important to ensure adequate ventilation and an effective fume removal system to maintain a safe and clean work environment.

Proper preparation and handling of materials

Before engraving, ensure that the materials are clean of dust and moisture and prepared according to the manufacturer's instructions. Also, care must be taken to properly handle the materials after engraving, including controlled cooling if necessary.

Frequently Asked Questions About Laser Engraving

How to deal with common engraving problems?

Common engraving problems include Uneven engraving and engraving Partial or superficialTo overcome these problems, ensure that the material is clean and properly aligned, and adjust the laser speed and power to the specific material. If the engraving is still not satisfactory, you can increase the laser power, slow down the speed, or make multiple engraving passes.

How to maintain and calibrate the laser engraving machine?

For proper maintenance and calibration of the machine Laser engraving, the head and mirror should be cleaned periodically, and consumable parts such as air filters should be replaced according to the manufacturer's instructions. It is also important to accurately calibrate the laser using dedicated software to ensure accurate and uniform engraving.

Advanced applications of laser engraving

Beyond standard engraving, it is possible to apply Advanced techniques Such as combined engraving and cutting, multiple layers of engraving, and embossing colors or other materials in the engraving. These techniques allow for the creation of unique and more complex effects on a variety of materials.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.