Precision sheet metal bending: how to choose the right machine

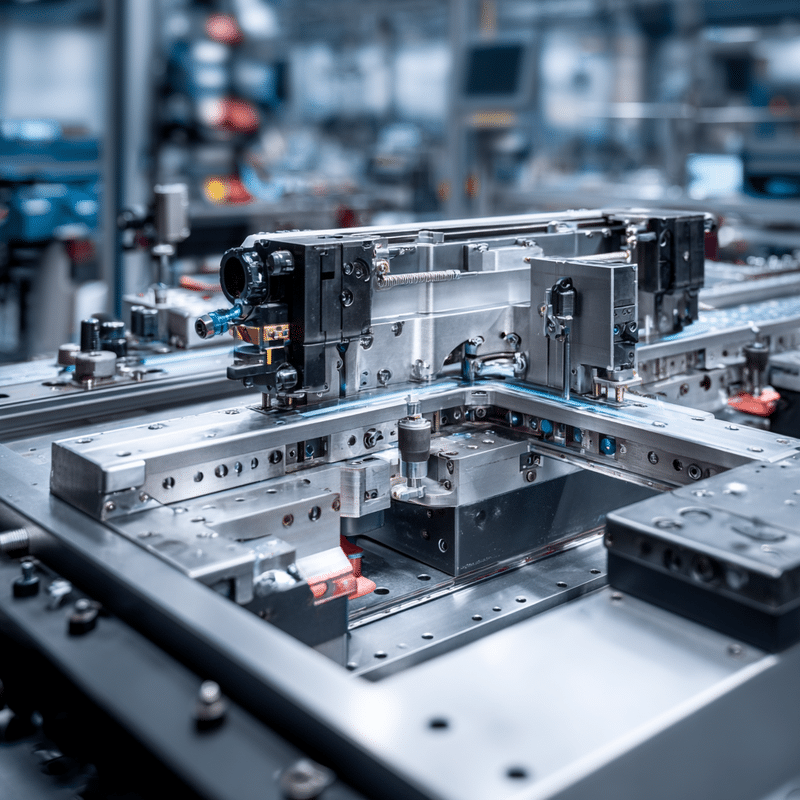

In the modern manufacturing world, sheet metal bending machines have become a key tool in metal design and processing. This technology enables maximum precision, high efficiency and flexibility in production, changing the way we approach metal processing. Let's dive deeper into this fascinating world and understand how these machines are impacting the industry.

The technological revolution in sheet metal bending

Modern sheet metal bending machines offer a level of precision and efficiency not previously possible. They allow for the creation of complex and precise shapes, while maintaining high quality and consistency in production. Advanced bending technology Allows companies to produce more complex products, in a shorter time and at a lower cost.

Key advantages of modern sheet metal bending machines

- Maximum bending accuracy

- High production efficiency

- Flexibility in design and production

- Saving time and costs

- Improving the quality of the final product

Types of sheet metal bending machines and their uses

There are several types of Bending machines Sheet metal, each tailored to specific industry needs. Hydraulic bending machines are very common due to their ability to handle thick and hard materials. Electric bending machines, on the other hand, excel in precision and energy efficiency.

| Machine type | Advantages | Common uses |

|---|---|---|

| Hydraulic bending machine | Great power, ability to handle thick materials | Automotive industry, construction |

| Electric bending machine | High precision, energy saving | Electronics, precision manufacturing |

| CNC bending machine | Automation, flexibility in production | Mass production, complex products |

The impact of sheet metal bending machines on various industries

Sheet metal bending machines impact a wide range of industries. In the automotive industry, for example, they enable the production of precise and durable body parts. In the aeronautics industry, high precision is essential for the production of critical aircraft parts. In the construction and architecture sectors, these machines also enable the creation of complex design elements.

Innovation and the future of sheet metal bending

Technological developments continue to improve the capabilities of sheet metal bending machines. Artificial Intelligence and Machine Learning are currently embedded in these systems, enabling optimization of production processes and continuous improvement of quality. In addition, Green technologies Embedded in these machines, they reduce energy consumption and the environmental impact of the production process.

Choosing the right sheet metal bending machine for your business needs

Choosing a bending machine A suitable bin is critical to the success of your business. There are several factors to consider:

- The type of materials to be processed

- Expected production volume

- The complexity of the required shapes

- Space and budget limitations

- Requirements for automation and integration with existing systems

It is important to consult with experts in the field to choose the most suitable machine. Companies like Everest Import Machinery Ltd. offer a wide range of solutions and can assist in choosing the right machine for the specific needs of each business.

Challenges and solutions in the use of sheet metal bending machines

Despite the many advantages, the use of sheet metal bending machines also poses challenges. One of the main challenges is The Springback Phenomenon, in which the metal tends to partially return to its original shape after bending. Advanced solutions, such as simulation software and advanced bending techniques, help overcome this challenge.

Training skilled personnel

As technology advances, it is becoming increasingly important to train skilled workers to operate advanced sheet metal bending machines. Comprehensive training programs, which include both theoretical and practical instruction, are essential to ensure the safe and efficient use of these machines.

The future of the sheet metal bending industry

The future of the sheet metal bending industry looks promising. Developments in the field ofSmart manufacturing and Industry 4.0 are expected to bring further improvements in efficiency and accuracy. Integration of technologies such as the Internet of Things (IoT) and advanced production management systems will enable real-time monitoring and continuous optimization of production processes.

In conclusion, sheet metal bending machines are a central pillar of modern industry, enabling precise, efficient and flexible production. As technology advances, we are expected to see further innovations that will further improve production capabilities and open up new possibilities in product design and manufacturing.

Integration of sheet metal bending machines into smart manufacturing systems

In the era of Industry 4.0, Integration of sheet metal bending machines into smart manufacturing systems is becoming a central issue. Advanced technologies allow bending machines to be connected to an overall production system, which improves efficiency and accuracy.

Benefits of integration in smart systems

- Real-time monitoring of bending processes

- Automatic optimization of production parameters

- Data-driven preventive maintenance

- Improved production scheduling and inventory management

Integration challenges and solutions

Despite the benefits, this integration poses technical and operational challenges. One of the key challenges is Compatibility between old and new systemsSolutions like customized APIs and data translation systems help overcome these gaps.

| challenge | solution |

|---|---|

| System compatibility | Customized APIs |

| Information security | Advanced encryption protocols |

| Employee training | Comprehensive training programs |

A look into the future: artificial intelligence in sheet metal bending

The future holds a more widespread implementation of Artificial Intelligence (AI) in Sheet Metal Bending ProcessesAI systems will be able to analyze historical and real-time data to predict potential problems, suggest process improvements, and even autonomously design complex manufacturing processes.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.