Pipe Bending Machine: The Comprehensive Guide to Revolutionary Technology in the Metal Industry

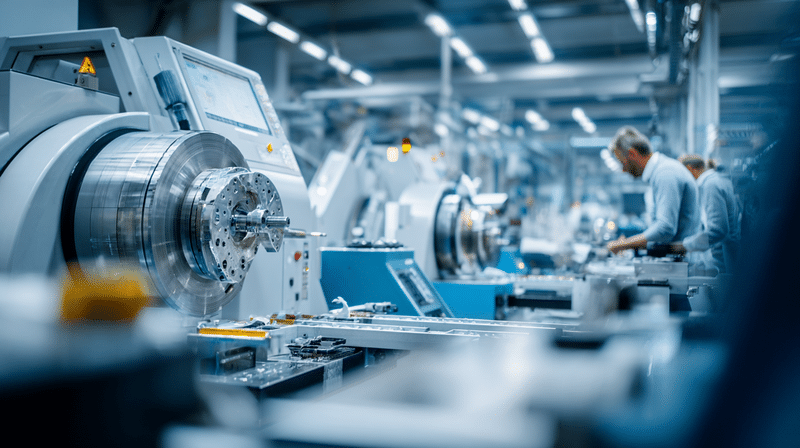

A pipe bending machine is an essential tool in the modern metalworking industry, allowing for the creation of complex and precise shapes in metal pipes. Whether you are an engineer, construction contractor, or furniture manufacturer, understanding the capabilities of this machine can significantly improve the quality and efficiency of your work. In this article, we will dive deep into the world of pipe bending, and discover how this technology is changing the face of the industry.

What is a pipe bending machine and how does it work?

Bending machine A pipe bender is a device designed to change the shape of straight metal pipes into rounded or angular shapes. It does this by applying controlled pressure to specific points along the length of the pipe, while maintaining the integrity of its structure. The process allows for the creation of precise bends at various angles, from subtle bends to complex shapes such as spirals.

The development of pipe bending technology

Over the years, pipe bending technology has undergone far-reaching changes. From simple manual machines, the industry has progressed to advanced hydraulic machines and computerized CNC systems. Today, modern bending machines are capable of performing extremely precise bends, using 3D software for design and control.

Main types of pipe bending machines

There are several types of pipe bending machines, each suited to specific needs:

- Bending machines Manual: Suitable for small projects and DIY work.

- Hydraulic bending machines: Provide more power and are suitable for working with thick pipes.

- CNC machines: allow for maximum precision and the ability to perform complex bends automatically.

Common bending techniques

There are several common bending techniques, each suited to different types of projects:

| Bending technique | Advantages | Common uses |

|---|---|---|

| Rotary bending | High precision, suitable for small radii | Automotive industry, furniture manufacturing |

| Scroll bending | Suitable for large diameter pipes | Construction, energy industry |

| Mandrel bending | Prevents wrinkles and reduction in diameter | Aviation industry, hydraulic systems |

Applications of pipe bending machines in various industries

Pipe bending machines are used in a wide variety of industries, each with unique requirements:

Automotive industry: exhaust systems and chassis components

In the automotive industry, tube bending machines are essential for creating complex exhaust systems and chassis components. The high precision of modern machines allows for a perfect fit to the vehicle design, while maintaining optimal gas flow and structural stability.

Aviation industry: fuel lines and hydraulic systems

In aviation, every gram of weight counts. Tube bending machines enable the creation of lightweight yet strong fuel lines and hydraulic systems that fit precisely into the tight spaces of aircraft. Accuracy and reliability are critical In this industry, where there is no room for error.

Construction Industry: Structural Support and Architectural Design

In the construction industry, pipe bending machines are used to create both structural and design elements. From safety railings to complex constructions, the ability to bend pipes with great precision allows architects and engineers to realize innovative ideas.

Advanced methods for improving efficiency in the use of pipe bending machines

To maximize efficiency when working with pipe bending machines, several advanced methods should be adopted:

Integration with computer-aided design (CAD) software

Integrating CAD systems with bending machines enables precise planning and optimization of the production process. This reduces the risk of errors and increases efficiency.

Using multifunctional systems

Modern machines offer the option of using a variety of tools on the same machine, allowing for greater flexibility in production and reducing the need to replace machines.

Real-time monitoring and control

Advanced monitoring systems allow for precise monitoring of the bending process, with the ability to make immediate adjustments as needed. This ensures high quality and consistency in results.

Safety when working with pipe bending machines

Safety is a critical aspect when working with pipe bending machines. It is important to:

- Use appropriate personal protective equipment, including goggles and gloves.

- Comprehensive training for all operators, including periodic refresher training.

- Regular maintenance of the machines to maintain their integrity and safety.

Future Trends in Pipe Bending Technology

The future brings with it exciting innovations in the field of pipe bending:

Advanced Automation and Robotics

Integrating advanced robotic systems is expected to increase accuracy and efficiency, while reducing the need for human intervention in production processes.

Green technologies and energy efficiency

Developing environmentally friendly bending machines that use energy more efficiently and reduce the carbon footprint of the production process.

Integrating artificial intelligence to optimize bending processes

Artificial intelligence systems will be able to analyze data in real time and make automatic adjustments, leading to continuous improvement in the quality and accuracy of the bending process.

Everest Machinery Import Company, specializing in importing advanced machinery for the metal industry, offers a wide range of pipe bending solutions that meet the most advanced requirements on the market. With innovative technologies and professional service, the company leads the way in this field in Israel.

Solving common pipe bending problems

Despite the many benefits of tube bending machines, problems sometimes arise that require professional solutions. Understanding common challenges and how to deal with them is critical to maintaining product quality and production efficiency.

Handling inconsistent bending angles

One common problem is inconsistent bend angles. The reasons for this can be varied, from wear on machine parts to changes in material properties. To solve the problem, the machine must be accurately calibrated. and ensure the use of materials of uniform quality.

Dealing with material shrinkage and elongation

The thickening and elongation of the material in the bending area can affect the strength and performance of the pipe. To reduce this phenomenon, techniques such as mandrel bending or adjusting the bending speed can be used. In some cases, changing the bend diameter or the raw material can solve the problem.

Overcoming challenges in bending different materials

Each material reacts differently to the bending process. For example, aluminum tends to be softer and requires gentle handling, while stainless steel may be more difficult to work with. Adjusting the machine settings to the specific material type is essential. To achieve optimal results.

| problem | Possible cause | Proposed solution |

|---|---|---|

| Inconsistent angles | Machine wear, material changes | Recalibration, material quality check |

| The density of the material | Unbalanced pressure, high bending speed | Using a mandrel, adjusting speed |

| Difficulty bending certain materials | Unique properties of the material | Adjusting settings for the material type |

Ultimately, success in solving bending problems depends on a combination of technical knowledge, practical experience, and the use of advanced technologies. With the right approach and the right tools, most challenges can be overcome and high-quality products can be produced efficiently.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.