The Precision Revolution: How Laser Engraving Machines Are Changing the Face of Industry

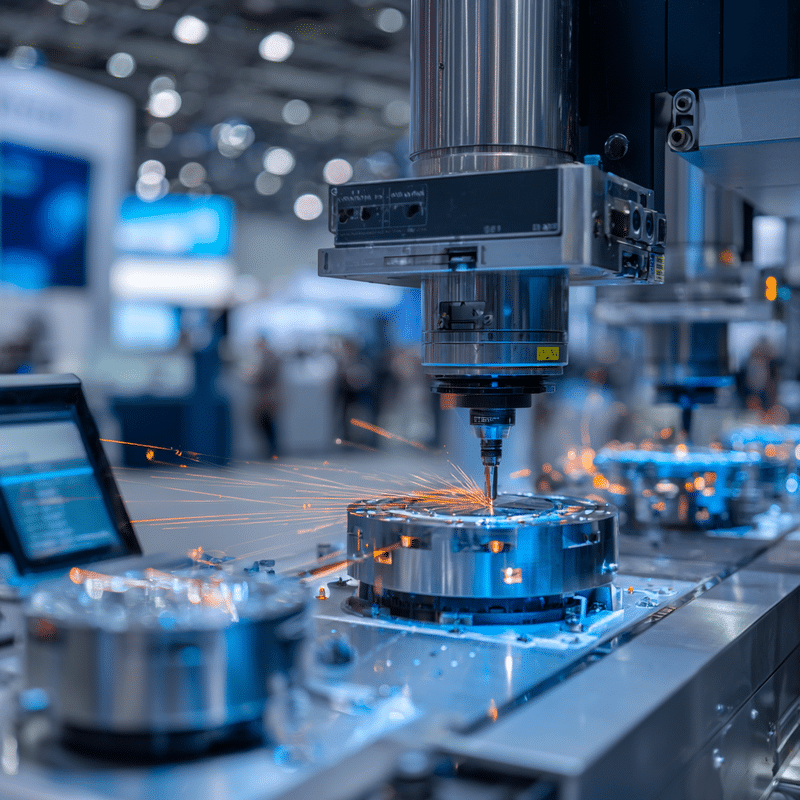

In the modern industrial world, laser engraving machines have become a key tool in precise and efficient manufacturing. This technology allows you to engrave and mark a wide range of materials with maximum precision, high speed and uncompromising quality. Let's dive into the fascinating world of laser engraving machines and examine how they are changing the face of industry.

Understanding the technology behind laser engraving machines

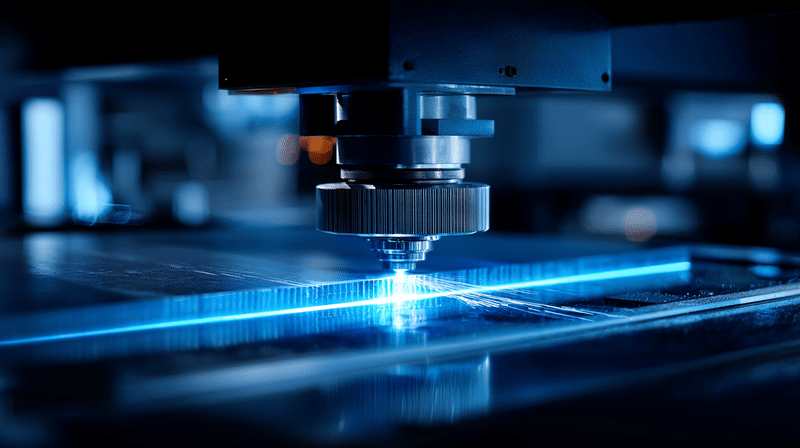

The scientific principle of laser engraving

Laser engraving is based on the principle of concentrating high-energy light onto a target surface. The focused beam heats and vaporizes the material, creating a marking or engraving. This process allows Micron precision And full control over the depth and quality of the engraving. The ability to control such precision opens up new possibilities in many manufacturing fields, from the electronics industry to jewelry design.

Main types of laser engraving systems

There are several main types of laser engraving machines, each with its own unique advantages:

- CO2 laser machines: Particularly suitable for engraving on organic materials such as wood, acrylic and glass.

- Fiber laser machines: Effective in engraving on metals and other hard materials.

- UV laser machines: They provide extremely high precision and are suitable for engraving on sensitive materials.

Advantages of laser engraving machines compared to traditional methods

Compared to traditional engraving methods, laser engraving offers significant advantages:

| criterion | Laser engraving | Traditional engraving |

|---|---|---|

| accuracy | Very high | Depends on the skill of the operator |

| speed | Very fast | Relatively slow |

| Flexibility in materials | Wide variety of materials | Limited to certain materials |

| Operating cost | Low long term | Depends on tools and materials |

Key components of a laser engraving machine

The laser source: the beating heart of the machine

The choice of laser source is critical to the efficiency of the machine. CO2 laser is suitable for organic materials, while fiber laser excels in working on metals. Everest Machinery Import Ltd., specializing in importing advanced machinery for the industry, offers a wide range of laser solutions tailored to customer needs, including innovative fiber laser machines.

Optical system: the eyes of the engraving machine

The optical system is responsible for focusing and directing the laser beam. The quality of the optical system directly affects the accuracy and quality of the engraving. High-quality mirrors and sanctifiers ensure Optimal performance Over time. Proper maintenance of the optical system is key to maintaining engraving quality over time.

Advanced applications of laser engraving machines in industry

A revolution in industrial production and product labeling

In industry, laser engraving machines are used to mark serial numbers, barcodes, and product information. They allow Sustainable labeling On a wide range of materials, from plastics to hard metals. This capability improves product traceability and enables the implementation of advanced inventory management systems.

Innovation in the personalized gift industry

In the world of personalized gifts, laser engraving machines open up new possibilities. Gift designers and creators can offer their customers almost unlimited personalization options, from engraving names on jewelry to intricate designs on wine glasses. The precision and flexibility of the technology allows for the creation of unique products easily and quickly, while maintaining high quality.

Choosing the right laser engraving machine for your business needs

In-depth assessment of engraving needs and budget

When choosing a laser engraving machine, it is important to consider the scope of the work, the types of materials, and the level of accuracy required. Long-term operating and maintenance costs must also be taken into account. Everest Import Machinery Ltd. offers professional advice on choosing the machine that best suits your business needs, taking into account all relevant parameters.

Power and Speed Considerations: Key to Efficiency

Laser power and engraving speed are critical parameters that affect work efficiency. Machines with higher power are suitable for deep engraving or working on difficult materials, while faster machines are suitable for high-volume production. The right balance between power and speed can lead to significant time and cost savings.

Safe operation and maintenance of laser engraving machine

Essential safety protocols

Safety is paramount when working with laser engraving machines. Care must be taken to use appropriate safety glasses, adequate ventilation, and automatic safety systems. Employee safety training is critical to preventing accidents. Everest Import Machinery Ltd. provides comprehensive safety training to its customers, ensuring a safe and efficient work environment.

Preventive maintenance: the key to machine longevity

Regular maintenance of the machine is essential to maintain optimal performance and long life. Regular cleaning of the optical system, checking of cooling systems, and periodic calibration are integral to the proper operation of a laser engraving machine. A well-organized maintenance program can prevent costly breakdowns and ensure continuous and efficient operation of the machine over time.

Economic benefits of using laser engraving machines

Long-term cost savings

The use of laser engraving machines offers Significant economic benefits For businesses in the long run. Despite the relatively high initial investment, the savings in operating and maintenance costs over time are significant. These machines require few parts replacements, consume energy efficiently, and reduce the need for expensive raw materials.

Increasing productivity and efficiency

Laser engraving machines allow Significant acceleration in production rateThe ability to perform complex work at high speed and with great precision leads to increased productivity and shortened delivery times. For example, a jewelry factory in Tel Aviv reported a 40% increase in productivity after implementing an advanced laser engraving machine.

Reducing waste and consumables

Laser technology enables more efficient utilization of raw materials, leading to a significant reduction in the amount of waste produced. In addition, the use of consumables such as ink or mechanical cutting tools is dramatically reduced, leading to further cost savings and reduced environmental impact.

Flexibility in production and rapid adaptation to market demands

Laser engraving machines allow High production flexibility, which allows businesses to respond quickly to changing market demands. The ability to change designs and make customizations without having to change tools or templates leads to time and cost savings, allowing businesses to be more competitive in a dynamic market.

| Economic advantage | Impact on the business | Average percentage improvement |

|---|---|---|

| Savings in operating costs | Reducing current expenses | 20-30% |

| Increasing productivity | Increase in revenue | 30-50% |

| Waste reduction | Saving raw materials | 15-25% |

| Production flexibility | Improvement in market response times | 40-60% |

In conclusion, investing in laser engraving machines offers a variety of economic benefits that positively impact a business's profitability and competitiveness. However, it is important to conduct a thorough analysis of the needs of the business and the specific market to ensure the viability of investing in this technology.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.