The Metal Design Revolution: The Power of Modern Iron Bending Machines

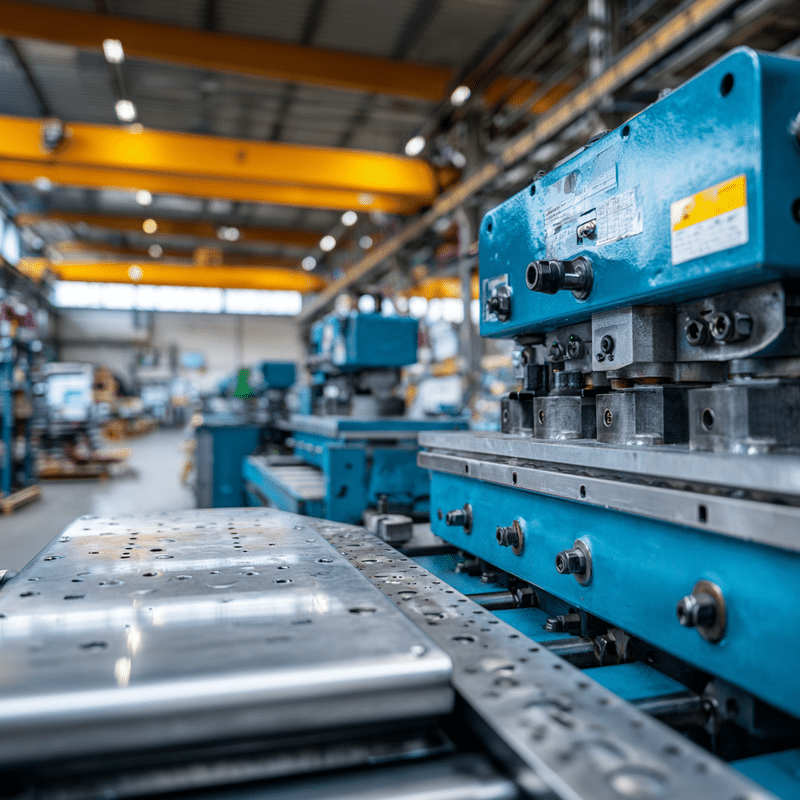

In the modern industrial world, Bending machines Iron has become a key tool in metal forming and processing. This technology is changing the face of the manufacturing industry, enabling maximum precision and high efficiency in work processes. Let's dive deep into the world of iron bending machines and examine how they affect the metal industry.

Understanding the mechanics of iron bending machines

Core components and their functions

Iron bending machine Consists of several essential parts, each of which plays a critical role in the design process. The central component is the pressing system, which is responsible for applying the force required to bend the metal. Alongside it, a precise control system allows full control over the bending angles and the intensity of the pressure.

Types of iron bending machines: manual vs. automatic

There are two main types of iron bending machines: manual and automatic. Manual machines are suitable for small, precise jobs, while automatic machines are designed for mass production and larger projects. Everest Machinery Imports Ltd. offers a wide range of iron bending solutions, tailored to different needs in the industry.

Principles of Operation: How Iron Bending Machines Work

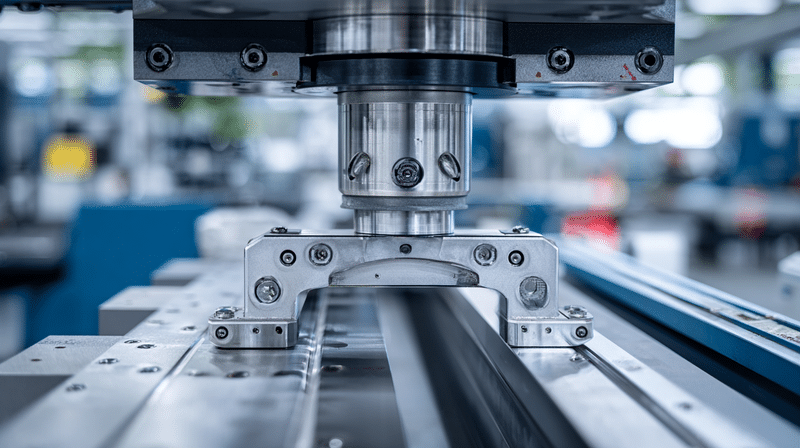

The bending process is based on the principle of metal plasticity. The machine applies pressure to a specific point on the metal plate, causing it to deform and take on the desired shape. The accuracy of this process Depends on several factors, including the type of metal, the thickness of the material, and the pressing force applied.

Applications and industries that use iron bending technology

Construction and infrastructure projects

In the construction industry, iron bending machines play a key role in creating structural components such as curved steel beams and stair railings. They enable the creation of complex shapes that were previously impossible, thereby expanding architectural possibilities.

Automotive manufacturing and custom fabrication

In the automotive industry, these machines are used to create body parts, frames, and interior components. The ability to bend metal with great precision allows for perfect fit of the parts and improves vehicle safety.

Artistic and architectural metal design

Artists and designers utilize technology to create spectacular sculptures and works of art from metal. In architecture, iron bending machines allow the creation of unique decorative elements that combine aesthetics and functionality.

Advantages of modern iron bending machines

Precision and quality in metal design

One of the most notable advantages of modern iron bending machines is the high level of precision they allow. Advanced technologies Such as computer control and laser measurement systems ensure accuracy of a few millimeters, which is especially essential in industries such as aviation and automotive manufacturing.

Increasing productivity and efficiency

Automated iron bending machines are capable of performing complex jobs at high speeds, significantly increasing productivity. This allows businesses to take on more orders and meet tight deadlines.

Economic efficiency and return on investment

Despite the initial investment, modern iron bending machines offer a quick return on investment. They reduce the need for manual labor, reduce waste, and enable more precise production, leading to significant savings in the long run.

Choosing the right iron bending machine for your needs

Weighing factors: capacity, speed, and versatility

When choosing an iron bending machine, several key factors should be considered:

- Capacity: The ability to handle the required metal thickness and length

- Speed: The rate of production required to meet business requirements

- Versatility: The ability to perform a wide range of bending operations

Comparing leading manufacturers and models

There are several leading manufacturers of iron bending machines on the market, each with its own advantages and disadvantages. Below is a comparison of some of the popular models:

| model | Maximum capacity | Working speed | Estimated price |

|---|---|---|---|

| Model A | 200 tons | 20 m/min | ₪500,000 |

| Model B | 150 tons | 25 m/min | ₪400,000 |

| Model C | 250 tons | 15 m/min | ₪600,000 |

Custom solutions vs. off-the-shelf solutions

While off-the-shelf solutions are suitable for most businesses, companies with unique requirements may need customized solutions. These solutions allow for precise adaptation to the needs of the business, but they are more expensive.

Maintenance and care of iron bending equipment

Routine inspection and cleaning procedures

Proper maintenance of a metal bending machine is essential to ensure optimal performance over time. Routine inspections of all moving parts should be performed, systems should be lubricated, and the machine should be cleaned of dust and metal shavings.

Troubleshooting common problems

Common problems with iron bending machines include inaccuracies in bending angles, accelerated wear of certain parts, and control system malfunctions. Early identification of these problems and prompt treatment can prevent long downtimes and high repair costs.

Extending the life of the machine through proper care

Proper care of a metal bending machine can significantly extend its life. This includes proper use of the machine, ensuring appropriate workloads, and regular preventive maintenance. Investing in maintenance Preventative maintenance can save high repair costs and ensure consistent performance over time.

Safety considerations when operating iron bending machines

Personal Protective Equipment (PPE) Requirements

Safety is a critical component when working with iron bending machines. Personal protective equipment It is mandatory for every operator, and includes:

- Chip-resistant safety glasses

- Reinforced work gloves

- Safety shoes with metal toe cap

- Headphones or earplugs for noise protection

Workplace safety protocols and best practices

Implementing strict safety protocols is essential to preventing accidents. These include:

- Daily checks of machine safety equipment

- Maintaining a clean and tidy work area

- Restrict access to the work area to authorized employees only

- Use clear warning signs

Example case: At the Israel Steel plant in Haifa, the implementation of strict safety protocols led to an 80% decrease in work accidents in the past year.

Operator training and certification

Comprehensive training is key to the safe operation of iron bending machines. A typical training program includes:

| Training topic | Duration of training | Refresh frequency |

|---|---|---|

| Basic safety | Two days | annual |

| Advanced machine operation | week | Every two years |

| Preventive maintenance | 3 days | Every two years |

“Proper training is the best protection against accidents,” notes Yossi Cohen, Safety Manager at the Standards Institute of Israel. “Qualified operators not only work more safely, but also identify and prevent potential hazards.”

Through strict implementation of these safety measures, a safe and efficient work environment can be ensured in the iron bending industry, while maintaining the health and well-being of employees.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.