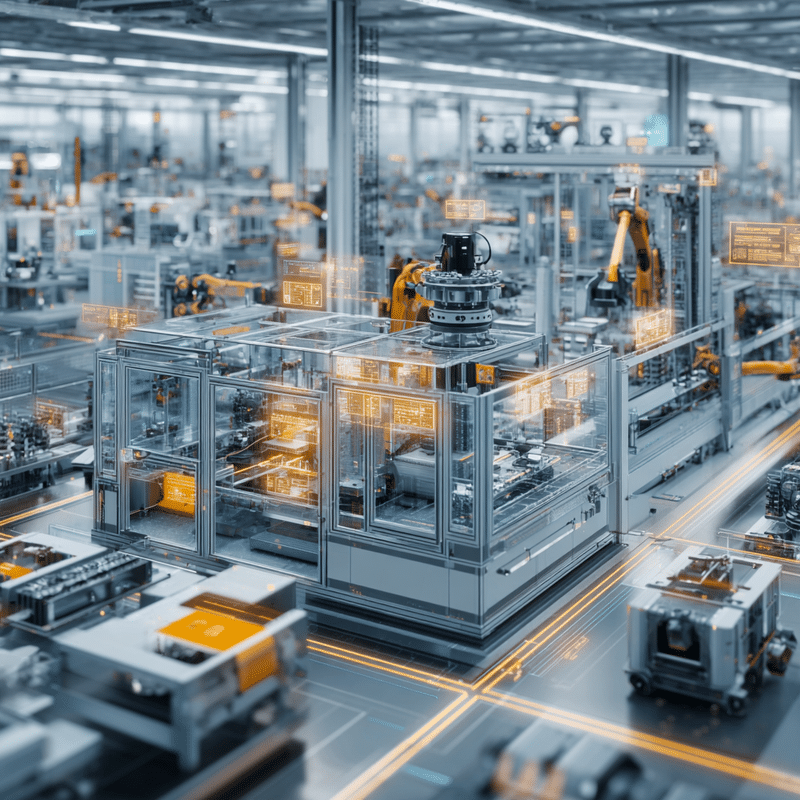

Industrial Automation: Improving Efficiency and Productivity

In the modern industrial world, industrial automation is the key to significantly improving efficiency and productivity. What is industrial automation, and why is it essential for companies in various industries? In this article, we will lay out everything you need to know about this important topic.

What is industrial automation?

Industrial automation refers to the use of mechanized systems and computerized controls to perform processes and tasks in an industrial environment. It involves the integration of hardware, software, control systems, and robotics to perform operations automatically, accurately, and consistently. The development of industrial automation began with the first industrial revolution, but received significant momentum with the invention of programmable logic controllers (PLCs) and industrial computing in the 1970s.

Advantages of industrial automation

Adopting industrial automation provides significant benefits to companies in various industries:

Increased productivity and efficiency

Automated systems can perform tasks continuously, quickly, and consistently, without tiring or stopping work. As a result, companies can increase production rates and improve their overall productivity.

Improving product quality and consistency

Industrial automation systems perform operations with high precision and uniformity, which reduces the risk of human error and ensures high product consistency.

Increasing employee safety

Industrial automation allows tasks that are dangerous or difficult to perform by humans to be transferred to automated systems, thereby reducing the risk of injuries and protecting workers.

Cost savings and competitive advantage

Although the initial investment in industrial automation can be high, it allows companies to save on labor costs, improve efficiency, and increase long-term profitability. It also provides a competitive advantage over non-automated companies.

Flexibility and adaptability

Modern industrial automation systems are flexible and can adapt to changing production and market demands. They allow companies to change production rates, switch models, and adjust processes more easily.

Types of industrial automation systems

There are several main types of industrial automation systems:

PLCs

PLCs are small industrial computers designed to control and monitor processes and machines in an industrial environment. They allow for logical programming of actions and responses to various situations.

Supervisory Control and Data Acquisition (SCADA) Systems

SCADA systems are used to remotely monitor and control industrial processes, by collecting real-time data from various signal generators and components.

Distributed Control Systems (DCS)

DCS are central control systems that combine controllers, software, and communication systems for the management and control of complex industrial processes.

Industrial robots and robotic automation

Industrial robots are computerized robotic arms designed to perform repetitive and precise tasks on the production line, such as assembly, welding, painting, and sorting.

CNC machines (computer numerical control)

CNC machines are Processing machines Performed by a computer, allowing for precise cutting, bending, or processing of materials according to a computer program.

Industrial Automation Applications

Industrial automation is used in a wide variety of industries and applications:

Production and industrial lines

Industrial automation systems are an integral part of modern production lines, in industries such as automotive, electronics, food and beverage, pharmaceuticals, and more.

Process control and monitoring

SCADA and DCS systems are used to control and supervise complex industrial processes, such as in the oil and gas, chemical, metals, and energy industries.

Material handling and logistics

Industrial and other mechanized robots perform material handling, transfer, packaging, and inventory management tasks in factories and logistics centers.

Quality control and testing

Cameras and computer vision systems are integrated into industrial automation for quality inspection, defect detection, and product control.

Packaging and assembly

Mechanized packaging and assembly lines enable fast, accurate and consistent execution of these tasks, while maintaining a high level of quality.

Challenges and considerations in industrial automation

Despite the many benefits, implementing industrial automation also involves certain challenges and considerations:

Initial costs and implementation

The initial investment in purchasing and implementing industrial automation systems can be high, and companies need to consider the long-term return on investment.

Integration with existing systems and infrastructures

Companies may need to adapt and integrate new automation systems with existing systems and infrastructure, which can be complex and expensive.

Training and upgrading employee skills

It is necessary to train employees in the operation, maintenance, and programming of the new automation systems, which requires investment in training and skills development.

Cybersecurity and information protection

Computerized industrial automation systems are exposed to cybersecurity risks, so it is important to implement appropriate security measures to protect data and systems.

Maintenance and troubleshooting

Industrial automation systems require regular maintenance and the ability to quickly locate and resolve faults, in order to prevent costly production downtime.

Future trends and forecast

The field of industrial automation continues to develop rapidly, and new trends are expected to impact the industry in the coming years:

Industry 4.0 and the Industrial Internet of Things (IIoT)

The Fourth Industrial Revolution focuses on the integration of digital technologies, the Internet, artificial intelligence, and robotics in factories and industrial processes. IIoT enables the connection and communication between various machines, components, and sensors.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning applications will enable companies to analyze data, identify patterns, and make data-driven decisions more effectively. They will also contribute to process improvement and increased automation.

Remote maintenance and monitoring

New technologies will allow companies to perform preventive maintenance and monitor the performance of systems and machines remotely, through the use of sensors, data analysis, and artificial intelligence.

Collaborative robots (cobots) and human-robot interaction

Cobots are robots designed to work collaboratively with humans in the same work environment, while maintaining safety and communication capabilities. They are expected to become more common in future production lines.

Sustainability and energy efficiency

In light of environmental concerns and rising energy prices, companies will look for ways to incorporate industrial automation technologies that are energy efficient and contribute to sustainability.

Successful planning and implementation of industrial automation

In order to get the most out of industrial automation, it is important to carry out an orderly process of Planning and executionThe main steps include:

Feasibility and feasibility assessment

The initial phase involves examining business needs and goals, analyzing existing processes, and assessing the potential for automation benefits. This is also an opportunity to examine potential costs and barriers.

Choosing the right automation solutions

After assessing the needs, you must choose the Automation technologies The most suitable ones, such as programmable logic controllers (PLCs), distributed control systems (DCS), industrial robots or CNC machines. This decision depends on the type of processes, budget and available resources.

System design and implementation

This stage includes Detailed planning of the new system, its adaptation to existing infrastructures and systems, and the actual implementation of the new technologies. It is important to consult experts and adhere to relevant standards and regulations.

Testing and troubleshooting

Before fully operating the system, you must perform Thorough tests To ensure that it is operating properly and to detect any potential faults or problems. This is also the stage for performing any necessary calibrations and adjustments.

Training and change management

To ensure successful implementation, it is essential to guide the The working force Using the new systems and managing the change process effectively. This includes outreach, training, and implementing an organizational culture that supports automation.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.