Industrial metalworking methods: from cutting to finishing

In the modern industrial world, metalworking is a vital process that enables the production of a wide range of products, from huge structures to tiny components. Advanced metalworking methods allow companies to produce high-quality products with precision and at a lower cost. In this article, we will review the different methods of metalworking in industry, from cutting and shaping to joining and finishing.

Metal cutting and shaping

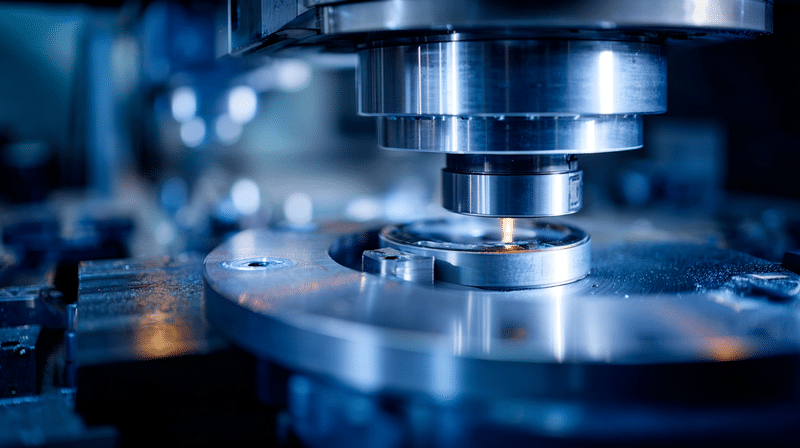

Cutting and milling processes

Cutting and milling are basic metalworking methods, allowing you to create complex shapes from materials such as steel, aluminum, and iron. Milling processes include milling with chip removal (such as milling, drilling and grinding), while Cutting methods They use sharp tools or energy sources such as lasers or water to cut the metal.

Laser and water cutting

Laser and water cutting are advanced metal processing methods that allow for precise and efficient cutting of a variety of materials. Laser cutting Uses a focused laser beam to cut through the metal, while Water cutting Utilizes high water pressure to cut hard materials. These methods are particularly suitable for machining thin walls or complex shapes.

Everest Machinery Import Ltd., the leading company in Israel in the field of importing advanced industrial machinery, offers a wide range of Laser cutting machines Advanced machines designed for precise processing of metals of various thicknesses.

Plasma and oxygen cutting

Plasma and oxy-fuel cutting are other metalworking methods that use high heat to cut the material. Plasma cutting utilizes a gas Hot ion for metal cutting, while oxygen cutting is particularly suitable for steel and is based on a chemical reaction of oxygen with iron.

Connecting and assembling metal components

Welding methods

Welding is an essential process in the metal industry that allows components to be joined together in a strong and durable manner. There are several Welding methods Common, such as:

- Electric welding (MIG, TIG)

- Arc welding

- Resistance welding

Choosing the appropriate welding method depends on the type of metal, the thickness of the material, and the specific requirements of the product.

Mechanical connections and fusion

Besides welding, there are other methods for joining metal components, such as Mechanical connections (screws, nails and rivets) andFusion (Soft and Strip Welding). These methods are suitable in cases where welding is impractical or when disassembly and reassembly capability is required.

Metal design and bending

Rolling, bending and shearing processes

Metal shaping includes a variety of methods for changing the shape of the material without removing parts of it. rolling Used to create cylinder and tube shapes, Bending Allows you to create angles and curvatures, andCrossing Used to create long profiles from solid materials.

Casting and pressing

Additional metal shaping methods include casting, in which liquid metal is poured into a mold, andpickling, which uses high pressure to compress metal into a desired shape. These methods are suitable for creating complex components or when a large quantity of identical products is required.

Surface treatment and finishing

Heat treatments and coatings

After processing the metal, it can be Heat treatments such as quenching, quenching and tempering to improve the material properties. In addition, Coatings Such as electrolytic, galvanizing and painting protect the metal from corrosion and improve its appearance.

Polishing and polishing

To obtain an aesthetic and shiny appearance, you can use methods Polishing and polishing Removing the top layers of the metal and polishing the surface. These processes are especially common in the jewelry and accessories industry.

| Processing method | Advantages | Disadvantages |

|---|---|---|

| Laser cutting | High precision, speed, ability to process complex shapes | High cost of equipment, limited to certain materials |

| Welding | Strong connection, flexibility in materials and shapes | Requires technical skill, risk of welding defects |

| casting | Ability to create complex shapes, suitable for mass production | High cost of molds, lower surface quality |

Advanced technologies in metal processing

Computer-aided manufacturing and 3D

With the advancement of technology, Computerized manufacturing (CNC) and3D printing (3D) are becoming more common in the metal industry. These methods allow for the accurate and rapid production of complex components using computer-aided design and control software.

Nanotechnology and smart materials

Studies in the field ofNanotechnology Leading to development Smart materials With unique properties, such as extremely high strength, corrosion resistance or special electrical properties. Incorporating these technologies into metal processing could lead to significant innovations in the industry.

Environmentally friendly processes

With the rise in sustainability awareness, many companies are looking Environmentally friendly metal processing methods More. Examples include using recycled materials, reducing waste and emissions, and moving to energy-efficient processes.

Quality control and testing

Non-destructive testing

To ensure the quality and safety of metal products, we useNon-destructive testing Such as radiography, ultrasonic waves, and eddy current. These methods allow for the identification of defects or imperfections in the metal structure without causing damage to the product.

Geometric measurements and materials analysis

Alongside non-destructive testing, Geometric measurements Ensures that the product meets dimensional requirements and permissible deviations. In addition, Materials analysis Chemical and physical allows you to verify the composition and quality of the metal.

Quality and control standards

To ensure high-quality and consistent metalworking processes, many companies implement Quality management systems and facts according to International standards Such as ISO 9001. These standards define best practices and requirements for quality control in the industry.

Standards and regulatory compliance

Beyond safety considerations, metal processing industries must operate in accordance withRules and regulations These include requirements regarding Emissions and air pollution, Waste treatment andProduct quality standardsCompanies are required to obtain Certifications and authorizations From the appropriate authorities.

Recycling and environmentally friendly practices

In addition to complying with regulations, many metal companies are adopting Environmentally friendly approaches such as Materials recycling, use ofEnergy-efficient technologies and minimization Pollutant emissionsThese practices contribute to sustainability and reduce the industry's carbon footprint.

Occupational safety and health

In order to protect Employee health, it is important to implement Occupational safety programs which include training, risk monitoring and prevention of exposure to hazardous factors. Must be provided Personal protective equipment and ensure compliance withSafety standards Strict.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.