Revolutionizing Metalworking: Innovative Techniques Reshaping Industrial Production

The world of metalworking has been undergoing a real revolution in recent years, with the development of innovative metalworking methods in the industry. These advanced technologies allow companies to produce products with greater precision, efficiency and lower costs. Let's dive into the leading methods that are reshaping industrial manufacturing processes.

The laser revolution in metal processing

אחת הטכנולוגיות המשמעותיות ביותר בתחום היא חיתוך בלייזר . שיטה זו מאפשרת דיוק ברמה מיקרונית, מהירות עבודה גבוהה ויכולת לעבד מגוון רחב של חומרים. חברת אוורסט יבוא מכונות בע"מ, המובילה בתחום ייבוא מכונות מתקדמות לתעשייה, מספקת מכונות פייבר לייזר מתקדמות המאפשרות לחברות ישראליות להתחרות בשוק העולמי.

Advantages of using laser technology:

- Extremely high accuracy

- Improved work speed

- Saving raw materials

- Ability to process a wide range of metals

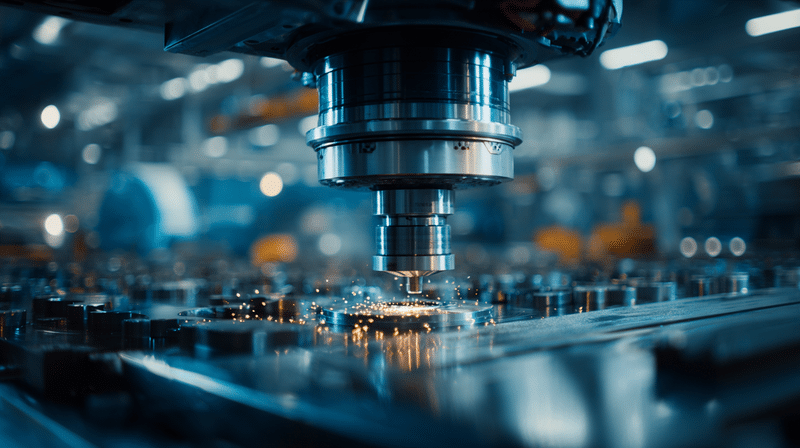

Computer-Aided Machining (CNC): Precision and Automation

CNC (Computer Numerical Control) technology is revolutionizing the field of chip processing. These machines enable the production of complex parts with high precision, using minimal human intervention.

Common applications of CNC machines in industry:

| Industry | Application |

|---|---|

| Aerospace | Manufacturing of precision engine parts |

| vehicle | Machining engine blocks and gearboxes |

| medicine | Manufacturing of implants and medical devices |

Electro-erosion (EDM): Precision shaping of hard metals

The EDM (Electrical Discharge Machining) method allows the machining of extremely hard metals and the creation of complex shapes that cannot be achieved with traditional methods. This technology is mainly used in industries that require extremely high precision, such as the mold industry.

Advantages of using EDM:

- Ability to process extremely hard materials

- High precision at the micron level

- Possibility to create complex shapes and sharp corners

Metal 3D Printing: The Future of Manufacturing

3D printing in metal, or Additive manufacturing, enables the creation of complex parts that cannot be produced using traditional methods. This technology is a revolution in the field of prototyping and customized manufacturing.

Common methods in metal 3D printing:

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Binder Jetting

Advanced welding: strong and precise connections

Innovative welding technologies allow for stronger, more precise, and higher quality joints. Methods such as electron beam welding and friction stir welding allow materials that were previously unweldable to be joined.

Advantages of advanced welding:

- High mechanical strength of the connection

- Possibility of welding various materials

- High precision and minimal distortion

Advanced Surface Machining: Improving Metal Properties

Advanced surface treatment technologies allow for improved metal properties, such as wear resistance, corrosion resistance, and aesthetic appearance. Methods such as plasma coating and ion nitriding provide innovative solutions to industrial challenges.

Automation and robotics in metal processing

Integrating automated systems and robots into metalworking processes enables continuous, efficient, and precise production. These technologies reduce the need for human intervention, increase productivity, and improve quality.

Advantages of automation in metal processing:

- Increasing productivity and efficiency

- Improving quality and consistency

- Reducing safety risks for employees

Challenges and opportunities in advanced metal processing

Despite the many benefits of innovative technologies, the industry faces several challenges. These include the need to train skilled personnel, dealing with the high costs of advanced equipment, and maintaining high standards of quality and safety.

However, the opportunities are enormous. Companies that adopt these advanced technologies can increase their manufacturing capabilities, develop innovative products, and compete in global markets.

Summary: The Future of Metalworking

Advanced metal processing methods in the industry continue to evolve and change the face of the field. Laser cutting From 3D metal printing to metal fabrication, new technologies are enabling companies to produce more complex, more precise products at lower costs. Adopting these technologies is key to success in today's competitive marketplace.

Advanced metal finishing and surface treatment processes

Finishing and surface treatment processes are a critical part of modern metalworking. Innovative technologies in this field allow for significant improvements in Metal properties, including corrosion resistance, mechanical strength and aesthetic appearance.

Anodizing: Creating a durable protective layer

Anodizing is an electrochemical process used primarily to treat aluminum. The process creates a hard, durable oxide layer on the surface of the metal, protecting it from corrosion and wear.

Powder coating: an environmentally friendly solution

Powder coating is a process green and effective used to protect metals from corrosion and improve aesthetic appearance. Unlike regular painting, this process does not use harmful solvents and provides a uniform and extremely durable coverage.

Shot peening: mechanical reinforcement of the surface

Shot peening is a process in which the surface of the metal is bombarded with small balls at high speed. The process improves the Metal fatigue resistance and extends the life of the product. This is an essential process in the aviation and automotive industries.

| process | Main advantages | Main industries |

|---|---|---|

| Anodizing | Corrosion protection, appearance improvement | Electronics, aviation |

| Powder coating | Eco-friendly, high durability | Furniture, electrical appliances |

| Pinning shot | Improved fatigue resistance | Aviation, Automotive |

It is important to note that choosing the right finishing process depends on many factors, including the type of metal, performance requirements, and cost. Properly planning finishing processes can lead to significant cost savings over time and improved quality of the final product.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.