The guide to choosing a fiber laser machine for factories in Israel

In the modern industrial world, Fiber machines Lasers have become a key tool for Israeli factories seeking to improve their efficiency and accuracy in metal processing. This guide is designed to help factory managers and entrepreneurs in Israel select the fiber laser machine that best suits their needs, while taking into account unique local factors.

Understanding Fiber Laser Technology in Industrial Applications

The science behind fiber laser cutting

Fiber laser technology is based on the use of optical fibers to transmit a high-intensity laser beam. The beam is focused on the surface to be cut, melting and vaporizing the material quickly and with great precision. This process allows for precise cutting of a wide range of metals, including steel, aluminum, copper and more.

Advantages of fiber laser machines for Israeli factories

For factories in Israel, the use of fiber laser machines offers several significant advantages:

- High accuracy: Allows the production of complex parts with minimal deviations.

- Processing speed: Increases production rate and shortens delivery times.

- Energy saving: Higher energy efficiency compared to traditional methods.

- Flexibility in materials: Ability to process a wide range of metals and alloys.

Comparison between fiber laser and traditional cutting methods

Compared to traditional cutting methods such as plasma or waterjet cutting, Fiber laser machines offer Significant advantages in accuracy, speed, and finish quality. They allow for thinner cutting with less thermal distortion, which is especially suitable for industries that require high precision such as the aeronautics and electronics industries.

Key factors in choosing a fiber laser machine for an Israeli factory

Estimating production needs and capacity requirements

לפני בחירת מכונת פייבר לייזר, חיוני להעריך את צרכי הייצור הספציפיים של המפעל. יש לשקול את סוגי המתכות שיעובדו, עובי החומרים, נפח הייצור הצפוי, ודרישות הדיוק. מפעלים ישראליים צריכים גם להתחשב בתנודות בביקוש ובאפשרות להרחבה עתידית.

Evaluating machine power and cutting capabilities

Laser power, measured in watts, is a determining factor in cutting capability. Higher-powered machines can cut thicker materials at higher speeds. However, power must be balanced against cost and the specific needs of the factory.

| Laser power (watts) | Maximum cutting thickness (mild steel) | Relative cutting speed |

|---|---|---|

| 1000W | Up to 8 mm | Basic |

| 2000W | Up to 12 mm | Fast |

| 4000W | Up to 20 mm | Very fast |

Material compatibility and versatility

It is important to choose a machine that can process the variety of materials required in the factory. Modern fiber laser machines are capable of cutting a wide range of metals, including steel, stainless steel, aluminum, copper, and even composite materials. Make sure that the machine you choose supports all the materials relevant to the factory's operations.

Speed and accuracy specification analysis

Cutting speed and accuracy are critical parameters when choosing a fiber laser machine. Advanced machines offer high cutting speeds while maintaining maximum accuracy, allowing for increased productivity without compromising quality. Speed and accuracy specifications should be examined in relation to the specific requirements of the products being manufactured in the factory.

Leading manufacturers of fiber laser machines in the Israeli market

Local suppliers and their offerings

The Israeli market offers a variety of local suppliers for fiber laser machines. Companies like Everest Import Machinery Ltd. provide advanced solutions to the Israeli industry, specializing in fiber laser and CNC machines. These local suppliers offer a significant advantage in local service availability and support.

International brands with a strong presence in Israel

Alongside local suppliers, many international brands are present in the Israeli market. These companies bring advanced technologies and global experience, while adapting to the demands of the local market. It is important to examine the history, reputation and local support offered by these brands.

Integrating fiber laser technology in the Israeli factory

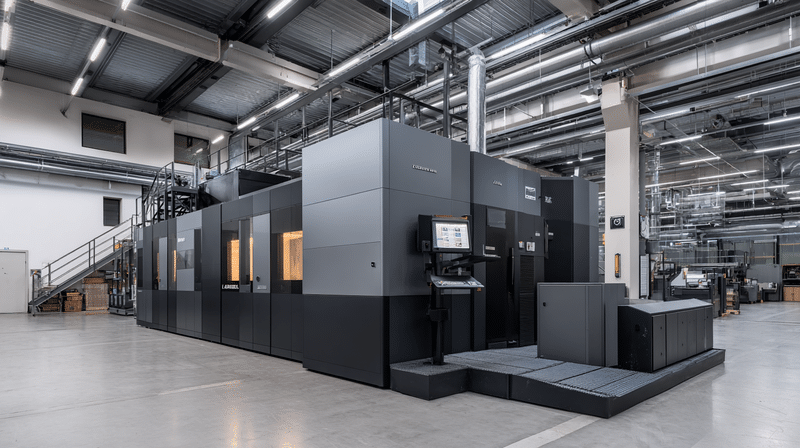

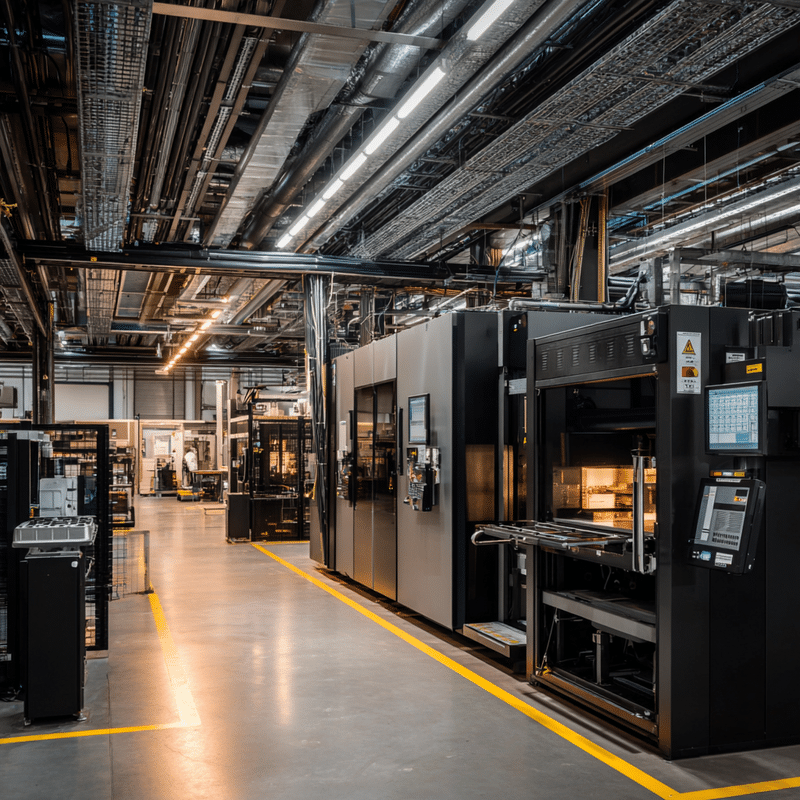

Space requirements and factory design considerations

Implementing a fiber laser machine requires careful planning of the workspace. The size of the machine, required safety zones, and supporting systems such as ventilation and material storage must be considered. Proper planning will ensure an efficient and safe workflow in the factory.

Training staff to operate fiber laser machines

Investing in employee training is critical to the success of integrating fiber laser technology. Comprehensive training should be provided on machine operation, routine maintenance, and safety. Proper training will ensure optimal utilization of the machine's capabilities and prevent malfunctions and production delays.

Cost-benefit analysis of fiber laser machines for Israeli manufacturers

Initial investment versus long-term productivity gains

למרות העלות הראשונית הגבוהה, מכונות פייבר לייזר מציעות החזר השקעה מהיר יחסית. היעילות המוגברת, הדיוק הגבוה, והיכולת לעבד מגוון חומרים מובילים לחיסכון משמעותי בעלויות ייצור לאורך זמן. יש לבצע ניתוח מעמיק של העלויות והתועלות הצפויות בהתאם לצרכי המפעל הספציפיים.

Calculating ROI for different industries and production scales

Return on investment (ROI) varies depending on the type of industry and the volume of production. For example, factories that manufacture precision parts in large quantities may see a faster return on investment compared to factories that focus on producing customized products in small quantities. It is important to conduct a detailed ROI analysis that considers all aspects relevant to the business.

Future trends in fiber laser technology for Israeli industry

Emerging innovations in laser cutting and engraving

The Israeli industry is set to see exciting developments in the fiber laser field. Future trends include the integration of artificial intelligence technologies to optimize cutting processes, the development of higher-power laser systems, and improvements in cutting accuracy and speed. Israeli manufacturers need to be aware of these innovations to maintain a competitive advantage.

Preparing your factory for next-generation laser technologies

To prepare for the future, Israeli factories should consider investing in flexible infrastructure that can accommodate new technologies. This includes training skilled workers, creating modular workspaces, and investing in advanced data management systems. This proactive approach will ensure that the factory can quickly adopt new technologies as they come to market.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.