The Ultimate Guide: When to Choose Fiber Laser and When to Choose CO2 for Precision Cutting

The world of laser cutting offers a variety of advanced technologies that allow businesses to work more efficiently and accurately. But with all the choices available, it can be difficult to decide which system to choose. Laser cutting is the right one for your specific needs. In this article, we’ll compare two leading laser cutting technologies – fiber laser and CO2 – and provide comprehensive guidance on choosing the perfect solution for your business.

Understanding laser cutting technology

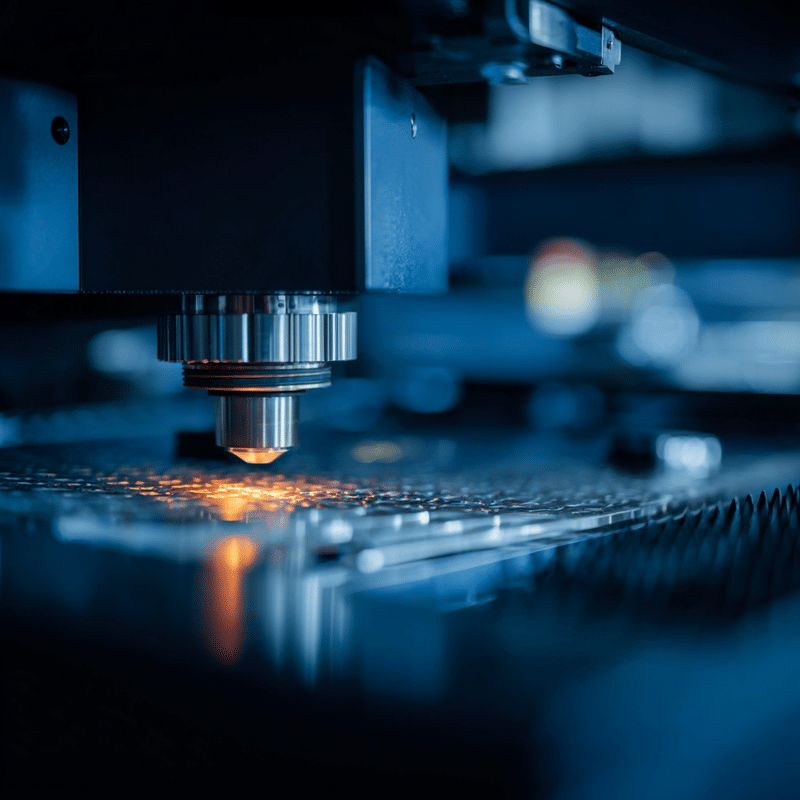

What is laser cutting?

Laser cutting is a process in which a highly focused laser beam is used to cut various materials, such as metals, plastics, wood, and more. The laser heats the material to the point of melting or vaporization, creating a precise and clean cut. This method offers many advantages, including high accuracy, speed of work, and resistance to abrasion.

Fiber Laser vs. CO2: An Overview

Fiber laser and CO2 are two laser technologies Leading to cutting Materials. Fiber lasers use special glass fibers to produce a powerful laser beam, while CO2 lasers produce a laser beam using a mixture of gases. Each of these technologies offers its own advantages and disadvantages, and the choice between them depends on the specific needs of the business.

Fiber Laser: The Innovative Cutting Solution

How do fiber lasers work?

Fiber lasers produce a laser beam using special glass fibers containing argon ions. When the glass fibers are illuminated by laser diodes, they produce a powerful laser beam with a very high energy density. This beam can cut through very thick metals with ease and precision.

Advantages of fiber lasers

High efficiency and low operating costs

Fiber lasers are very energy efficient, leading to significant savings in operating costs. They also require less maintenance and repairs than other laser technologies.

Compact and maintenance-friendly design

מערכות פייבר לייזר הן קטנות יותר וקלות יותר לתחזוקה בהשוואה למערכות לייזר מסורתיות. הן תופסות פחות שטח ויכולות להיות ממוקמות בקרבת עמדות העבודה.

Flexibility in cutting materials

Fiber lasers can cut a wide range of metals, including mild steel, stainless steel, aluminum, and more. They are also suitable for cutting certain non-metallic materials, such as plastics and ceramics.

Limitations of Fiber Lasers

Despite the many advantages of fiber lasers, they are still limited in cutting certain non-metallic materials, such as wood and fabric. They may also be less effective at cutting very thick metals compared to other laser technologies.

CO2 laser: the old and proven tool

Understanding CO2 Laser Technology

CO2 lasers produce a laser beam using a mixture of gases, primarily carbon dioxide (CO2), helium, and nitrogen. When the gases are illuminated by an electrical discharge, they produce a laser beam with a unique wavelength that is particularly suitable for cutting non-metallic materials.

Advantages of CO2 lasers

Outstanding cutting quality for non-metallic materials

CO2 lasers are known for their high cutting quality for non-metallic materials, such as wood, fabric, plastic, and more. They provide clean, smooth cuts, without scratches or defects.

Wide range of material compatibility

In addition to non-metallic materials, CO2 lasers can also cut a wide range of metals, including mild steel, stainless steel, and aluminum.

Proven reliability and durability

CO2 lasers are a proven technology that has been in industrial use for decades. They are known for their reliability and long-lasting durability.

Disadvantages of CO2 lasers

Higher operating costs

CO2 lasers consume more energy and require more maintenance compared to fiber lasers, leading to higher operating costs.

Larger footprint and high maintenance requirements

CO2 laser systems are larger and take up more space. They also require more frequent maintenance and routine repairs.

Choosing the right laser cutting solution

Material considerations

Metals: When to choose a fiber laser?

If your business primarily deals with cutting metals, such as mild steel, stainless steel, or aluminum, fiber lasers are the recommended choice. Fiber lasers offer high efficiency, low operating costs, and great flexibility in cutting a wide range of metals.

Non-metallic materials: the strengths of CO2 lasers

On the other hand, if your business focuses on cutting non-metallic materials such as wood, fabric or plastic, a CO2 laser is the preferred solution. CO2 lasers offer high cutting quality for these materials, with clean and smooth cuts.

Considerations by application and industry

Automotive and aviation industries

In the automotive and aerospace industries, fiber lasers are considered the preferred solution due to their ability to cut metals with high precision and speed. They enable the efficient production of complex metal components and items.

Production and industry

In manufacturing and industrial applications, the choice between a fiber laser and a CO2 laser depends on the variety of materials to be cut. If the majority of the materials are metals, a fiber laser is the best choice. If non-metallic materials need to be cut, a CO2 laser may be the more appropriate solution.

Signage and engraving

For signage and engraving applications on non-metallic materials such as wood, plastic or acrylic, a CO2 laser is the preferred solution. It allows for high-resolution cutting and smooth, high-quality results.

Cost and efficiency analysis

Initial investment and operating expenses

While CO2 lasers may be more expensive in the initial investment, fiber lasers consume less energy and require less maintenance, leading to significant savings in long-term operating costs.

Energy consumption and environmental impact

Fiber lasers are more environmentally friendly due to their low energy consumption. CO2 lasers, on the other hand, consume more energy and leave a larger carbon footprint.

Space and facility requirements

Laser space and footprint limitations

Fiber lasers are more compact and take up less space, making them an ideal choice for smaller factories or workshops. CO2 lasers, on the other hand, require more space due to their larger size.

Ventilation and safety considerations

Both types of lasers require proper ventilation systems to remove smoke and fumes. However, CO2 lasers may require more stringent safety and ventilation requirements due to the toxic gases used in the laser process.

Hybrid cutting solutions

While fiber lasers and CO2 lasers offer unique advantages, there is also the option of combining these two technologies together in a hybrid cutting solution. These solutions combine a fiber laser and a CO2 laser in the same device, allowing for tremendous flexibility in cutting a wide range of materials.

Combining fiber laser and CO2 technologies

In hybrid cutting systems, the fiber laser Used for cutting metals efficiently and accurately, while the CO2 laser specializes in cutting non-metallic materials such as wood, plastic and fabric. This combination allows factories and workshops to handle a wide range of cutting requirements using a single device.

Advantages of hybrid cutting systems

Increased flexibility and material range

Hybrid cutting solutions allow for tremendous flexibility in cutting a wide range of materials, from metals to non-metallic materials. This is an important feature for factories and manufacturers looking to improve their efficiency and expand their product range.

Optimal cutting performance

Hybrid cutting systems utilize the advantages of each laser technology for the appropriate materials, ensuring Optimal cutting performance and quality results for any type of material.

An efficient and cost-effective solution

By combining two laser technologies in one device, hybrid cutting systems offer an efficient and cost-effective solution. They save on initial investment and long-term operating costs, while maintaining flexibility and high performance.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.