The effect of beam quality on the efficiency and ability to cut metals with a fiber laser

In the modern industrial world, precision is the key to prosperity. For metal manufacturers, achieving precise and consistent cuts is essential to ensuring high product quality and process efficiency. At the heart of the ability to cut metals perfectly is advanced fiber laser cutting technology, which Foundation quality It is a critical factor. In this chapter, we will explore the profound impact of beam quality on metal cutting performance and discover how precision can be maximized through intelligent control of beam quality.

Introduction to Beam Quality and Fiber Laser Metal Cutting

What is the quality of the foundation?

Beam quality refers to the spread and concentration pattern of the laser beam. A high-quality beam has a narrow, focused spread pattern, allowing for higher energy concentration in the cutting spot. In contrast, a low-quality beam spreads unevenly and diffusely, making it difficult to achieve precise, uniform cutting.

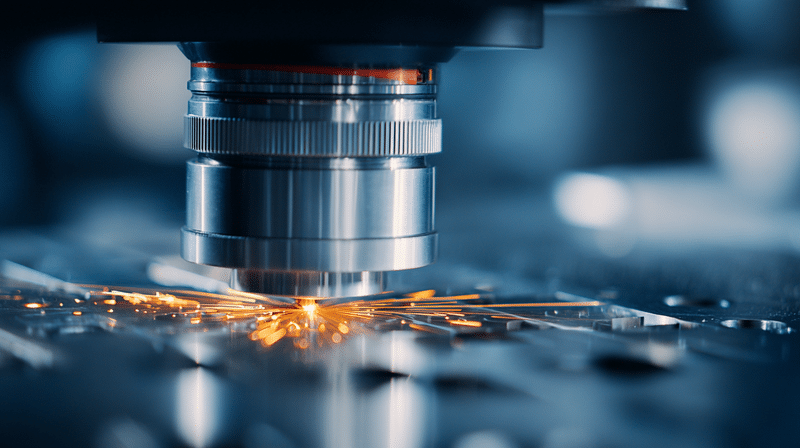

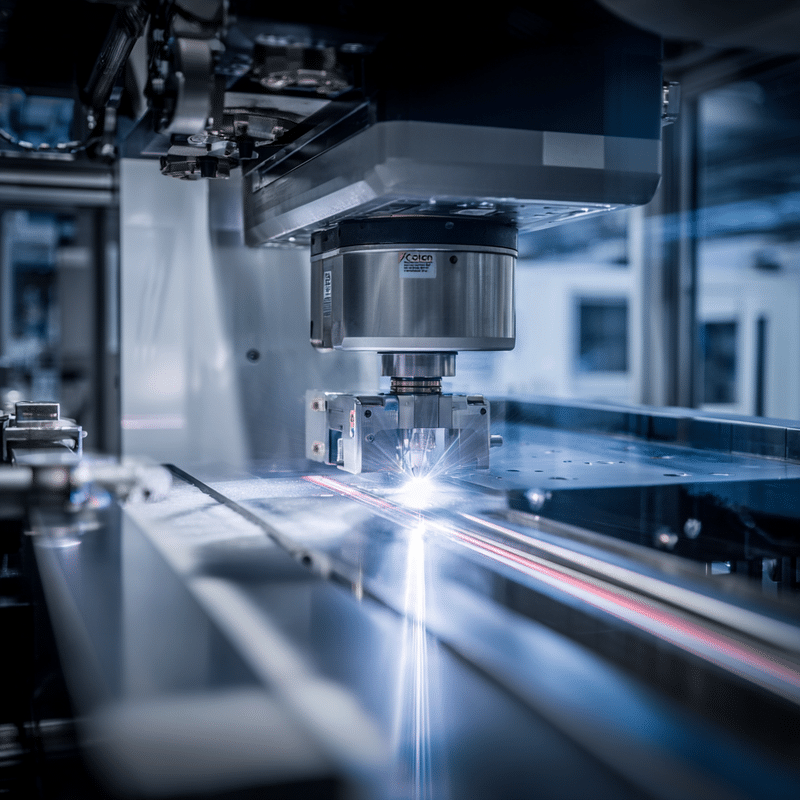

Overview of Fiber Laser Metal Cutting Technology

חיתוך מתכות בפייבר לייזר הוא תהליך בו קרן לייזר בעלת עוצמה גבוהה מרוכזת על משטח המתכת כדי לחתוך דרכה. הלייזר מתחמם את המתכת עד לנקודת ההתכה או האידוי, ובשילוב עם זרם גז דחוס, מסלק את החומר הנוזלי או הגז מאזור החיתוך. תהליך זה מאפשר חיתוכים מדויקים ביותר עם שוליים חלקים וזוויות חדות.

The importance of beam quality in laser cutting applications

Beam quality directly affects the cutting performance of a fiber laser system. A high-quality beam allows for maximum energy concentration in the cutting area, leading to more precise cuts, smoother edges, and sharper corners. On the other hand, a low-quality beam can result in uneven cuts, rough edges, and rounded corners. As a result, controlling beam quality is critical to achieving accurate and consistent metal cutting results.

Factors affecting the quality of the foundation

Laser source characteristics

Beam quality is largely influenced by the characteristics of the laser source itself. Factors such as laser type, wavelength, power, and operating mode affect the beam propagation pattern and overall quality. For example, fiber lasers often offer higher beam quality than traditional CO2 lasers.

Foundation transfer system design

The beam delivery system, which includes the optical fibers and lenses, also affects the beam quality. Distortions or instability in the delivery system can cause unwanted beam spreading and degradation of beam quality. Therefore, a perfect design of the delivery system is essential to achieve high beam quality.

Environmental conditions and thermal effects

Environmental factors such as temperature, humidity, and vibration can affect beam quality. Thermal effects from the laser itself can also cause beam distortion and degrade beam quality. Therefore, environmental control and thermal management measures are essential to ensure stable and consistent beam quality.

Measurement and evaluation of foundation quality

Beam Spread Ratio (BPR) and M-Squared

Beam propagation ratio (BPR) and M-Squared are common metrics for measuring beam quality. BPR compares the actual beam propagation to that of an ideal Gaussian beam, while M-Squared provides a quantitative measure of beam quality. Lower values of BPR and M-Squared indicate higher beam quality.

Foundation Profiling Techniques

Beam profiling techniques involve the use of specialized cameras and analysis systems to visually display the beam propagation pattern. Beam profiling provides important visual information about beam quality and allows for the identification of potential problems.

Interpretation of beam quality measurements

Correct interpretation of beam quality measurements is critical to understanding the implications for cutting performance. These measurements provide quantitative and visual data that can help identify causes of poor beam quality and determine corrective actions needed to improve beam quality.

The influence of beam quality on cutting performance

Cutting quality and edge finishing

The quality of the beam directly affects the quality of the cut and the edge finish of the cut. A high-quality beam allows for smooth, precise cuts with sharp edges and right angles. Conversely, a low-quality beam can result in rough cuts, uneven edges, and rounded corners.

Cutting speed and efficiency

The quality of the beam also affects the cutting speed and process efficiency. A high-quality beam allows maximum energy concentration in the cutting area, which allows for higher cutting speeds without compromising cut quality. As a result, higher process efficiency can be achieved and production times can be shortened.

Material processing capabilities

The quality of the beam also affects the ability to process different materials. A high-quality beam allows for cutting a wider range of materials, including harder and thicker metals. This is especially essential in industries such as aerospace and automotive, where the ability to process specialized and complex materials is required.

Beam quality optimization for improved cutting results

Alignment of the laser source and optics

Accurate alignment of the laser source and optical components is a crucial step in achieving high beam quality. Slight deviations in alignment can cause distortions in the beam and impair its quality. Therefore, professional alignment and regular maintenance of the system are essential.

Beam design and mode control

Beam shaping and mode control techniques allow further improvement of beam quality. For example, the use of special lenses and mirrors can help improve beam concentration and reduce beam spread. Also, controlling the frequency modes of the beam can improve beam quality and adapt it to specific applications.

Thermal management strategies

Proper thermal management of the system is essential to ensure consistent beam quality. Techniques such as active cooling, thermal insulation, and temperature monitoring can help minimize adverse thermal effects and maintain high, consistent beam quality.

Technological innovations and future trends in foundation quality control

Adaptive optics and wavefront correction

Innovative technologies of Adaptive optics Enables dynamic correction of distortions in the wavefront of the laser beam, thus Significant improvement in foundation qualityThese systems use deformable mirrors or liquid cells to correct distortions in real time, ensuring high and consistent beam quality.

Integrated monitoring and feedback systems

Monitoring and control capabilities Improved systems allow for the detection and correction of beam quality deviations during the process. These systems include sensors to monitor beam quality and feedback loops to automatically adjust the relevant parameters, ensuring Consistent and reliable performance.

Innovative laser technologies and beam shaping methods

Developments in the field of lasers themselves, such as Femtosecond lasers and focused beam lasers, offer Improved beam quality and new capabilities. In addition, innovative beam design methods, such as mode-specific design, allow for precise beam tuning for specific applications and different materials.

Additional articles:

פרמטרים חשובים לפני רכישת מכונת פייבר לייזר: מדריך מקיף לבחירה נכונה

ההבדלים המשמעותיים בין מכונות לייזר מקצועיות למכונות פשוטות

מכונת חיתוך וחריטה בלייזר לתעשייה

We are here to help with any issue or question.