A Comprehensive Guide to Controlling a Panel Bender Machine: Introduction, Selection, and Optimizing Bending Processes

Are you planning to purchase a panel bender machine for your business or are you already working with one? Whether you’re new to the world of panel benders or a seasoned expert, understanding the finer details and advanced techniques can save you a lot of time and money. In this comprehensive guide, we’ll cover everything you need to know about panel benders – from the basic components to the most advanced techniques.

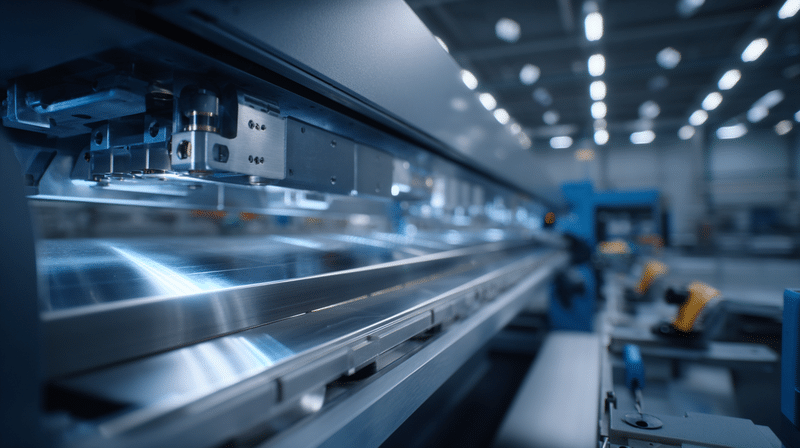

What is a panel bender machine and what are its advantages?

Machine Panel bender It is an industrial device designed for bending and shaping thin metal sheets. Using pressure or hydraulic power, the machine is able to create precise and complex folds in the metal sheets, allowing the creation of diverse three-dimensional structures. These machines are common in a variety of industries, including automotive manufacturing, electrical appliances, office furniture, and more.

Benefits of using a panel bender machine

- High precision: modern panel bender machines Allows bending Precision of metal plates down to the level of a few millimeters, which ensures high quality of the final product.

- efficiency: The mechanized bending process enables fast and consistent production of products, while saving time and manpower.

- flexibility: The machine can be adapted to different types of materials and thicknesses, allowing for a wide variety of products and applications.

- safety: Modern panel bender machines include advanced control systems and safety measures, which protect workers from injuries.

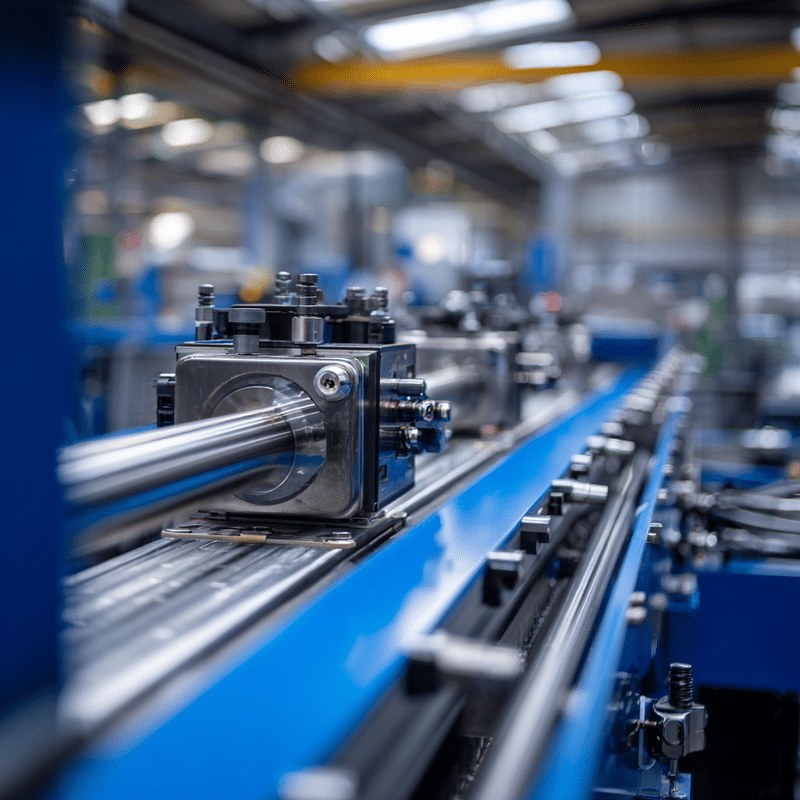

Understanding the components of the panel bender machine

In order to get the most out of your panel bender machine, it is important to know its main components and their function. Let's start with the main mechanical parts:

Main parts and mechanisms

- Machine body: The central frame of the machine, which holds all the other components.

- Bending arm: The mechanical arm that applies the pressure or force needed to bend the board.

- Work surface: The adjustable surface on which the metal plate rests during bending.

- Board brackets: Mechanisms that hold the metal plate in place during bending.

Advanced panel bender machines also include computerized control systems and touch screens for easy control of the bending process. They are also equipped with safety features such as finger guards, emergency stops, and fault detection systems.

Choosing the right panel bender machine

There are several main types of panel bender machines, each suited to different needs and requirements. When choosing the right machine, it is important to consider the following factors:

Types of Panel Bender Machines

- Manual machines: Relatively simple machines, operated by the worker's physical strength. Suitable for small, individual jobs.

- Hydraulic machines: Machines that utilize liquid pressure for bending. They allow for great force and are suitable for working with thick plates.

- Electrical machines: Computerized machines powered by electric motors. Highly accurate, but more expensive.

Factors for choosing a panel bender machine

- Material type: Will you need to work with steel, aluminum, stainless steel or other materials?

- Thickness of the boards: Different machines are suitable for different thickness ranges of metal plates.

- Required bending radius: The smaller the required radius, the more advanced the machine required.

- Work volume: Larger machines are suitable for mass production, while small machines can suffice for smaller businesses.

Everest Machinery Import Ltd., which specializes in importing advanced machinery for the industry, can assist you in choosing the panel bender machine that best suits your business needs.

Gaining full control of the panel bender machine

Once you have chosen the right panel bender machine, it is time to start working with it. To achieve professional and safe results, it is important to know the requirements for the installation and proper operation of the machine.

Installation and working environment requirements

- Enough space: Make sure you have enough free space to install the machine and move around it freely.

- Electrical and compressed air connections: Make sure you have appropriate connection points for electricity and compressed air (for hydraulic machines).

- Adequate lighting: A well-lit work environment will allow you to clearly see the metal sheet and the bending process.

- Personal protective equipment: Equip yourself with work gloves, safety glasses, and other safety equipment according to the manufacturer's instructions.

The bending process step by step

- Insert the metal plate into the machine and attach it to the work surface using the plate clamps.

- Adjust the bending angle, pressure intensity and arm position using the control system.

- Start the bending process using the appropriate button or handle.

- Monitor the bending process and make any necessary adjustments during it.

- After bending, carefully release the metal plate and check the result.

With time and experience, you will be able to more easily control the panel bender machine and achieve accurate and consistent results.

Advanced panel bending techniques

Once you have mastered the basics of using the panel bender machine, you can progress to more advanced techniques, which allow for the creation of complex bending patterns and unique designs.

Complex bending patterns and unique designs

By combining multiple bends at different angles, complex and spectacular three-dimensional structures can be created. These techniques are common in the design of furniture, lighting fixtures, and metal art products.

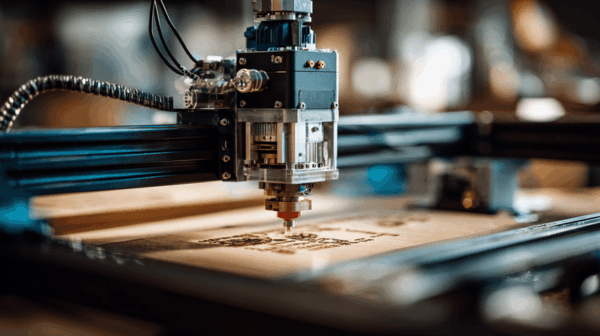

Combining panel bender machines with CNC machines

By combining a panel bender machine with CNC (Computer Numerical Control) machines For cutting and processing metal, it is possible to create extremely complex and precise products. This combination enables full automation of production processes and significantly shortens work times.

Automation of bending processes

Advanced panel bender machines feature advanced automation capabilities, allowing entire production programs to be run without manual intervention. This is a particularly efficient way to mass produce identical products.

Common spare parts and repairs

After years of use, some parts of the panel bender machine may wear out and require exchangeCommon parts to replace are:

- Board brackets: These parts bend the board and may wear out over time.

- Bending arms: The arms that bend the board may become bent or weakened.

- Sliding rails: The rails that allow the board to move may become warped or cracked.

- Control systems: Electrical and electronic components may fail and require repair or replacement.

In cases of malfunction or malfunction, it is important to contact the manufacturer or an authorized service center for Professional repairAttempting to repair the machine yourself may cause further damage.

Safety considerations during maintenance

When performing maintenance or repairs on the panel bender machine, it is important to take Appropriate safety measures:

- Disconnect the machine from the power source before performing maintenance work.

- Use personal protective equipment such as gloves, goggles and appropriate clothing.

- Follow the manufacturer's safety instructions and local safety regulations.

Additional articles:

איך מכונת פייבר לייזר ממירה אנרגיה לחום: כל מה שצריך לדעת על טכנולוגיית הלייזר

פתחו עסק רווחי בעזרת מכונת חיתוך ולייזר

מכונות כיפוף צינורות נירוסטה

We are here to help with any issue or question.